Ball Valves vs. Butterfly Valves

Ball Valves vs. Butterfly Valves: Which Do You Need?

When designing and building a piping system — whether it’s for food and beverage production, municipal water transport or biochemical processing — it’s critical to use the correct type of valve. Doing so ensures that your piping system runs smoothly, and that maintenance and repairs can be performed as needed.

Here, we cover the differences and similarities between ball valves and butterfly valves, including when to use one over the other.

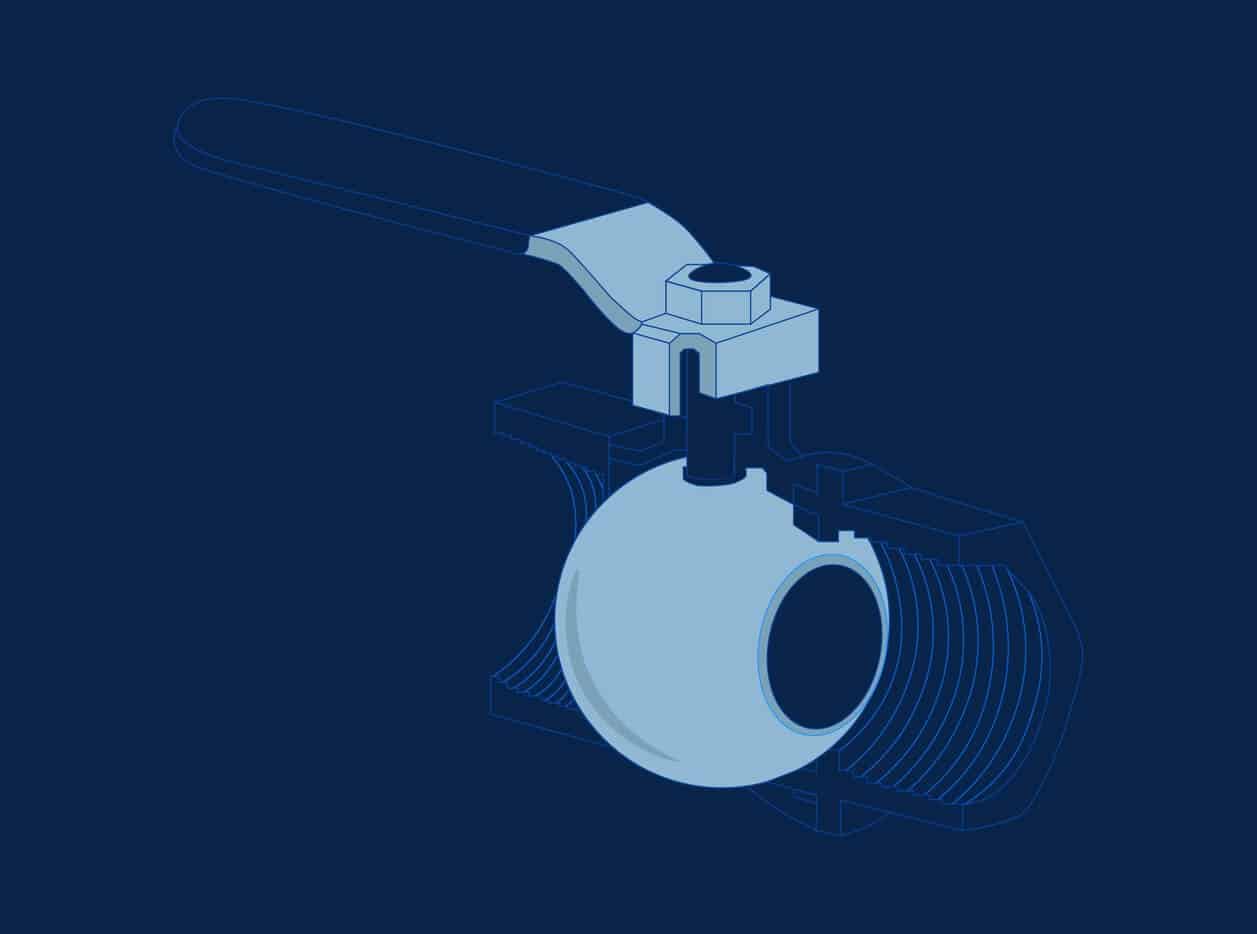

Ball Valves

Ball valves are quarter turn, on/off valves that control the flow of liquid or gas media. As the name implies, they rely on a hollow pivoting ball, which rotates 90° to halt or allow media to pass through the port (or bore).

Ball valves operate through automatic or manual actuation; they can be operated via pneumatic, hydraulic or electric power, or manually operated most commonly via a lever handle. The position of this lever provides a visible cue to indicate whether the valve is open or closed. Ball valves offer a faster option for on/off media control than valves that require a full turn or multiple turns to reach their open or closed positions.

One- or two-way ball valves have a single port through the center of the ball, but there are multi-port ball valves available for applications that require the diversion (or selection) of media in multiple directions, or that handle media from different sources in the piping system. Ball valves are available in full-port, standard port, reduced-port, and V-port configurations. There are also a variety of body designs to choose from such as 1-piece, 2-piece, and 3-piece bodies.

Most ball valves can operate in relatively high pressure environments, as well as in a wide media temperature range. with minimal pressure drop. (Full-port ball valve designs prevent pressure drop altogether.)

When to Use Ball Valves

Ball valves are widely favored for their durability, versatility, fast cycle time and leak-tight seal, and are frequently used in a wide variety of industrial and residential applications. They can handle both fluid and gas media and enable process pigging, a cleaning method in which a device called a pig is pumped through pipes to clean them. However, despite their versatility, ball valves are not recommended for control applications where extremely precise flow control is required.

Ball valves are found in piping systems in the following industries and applications:

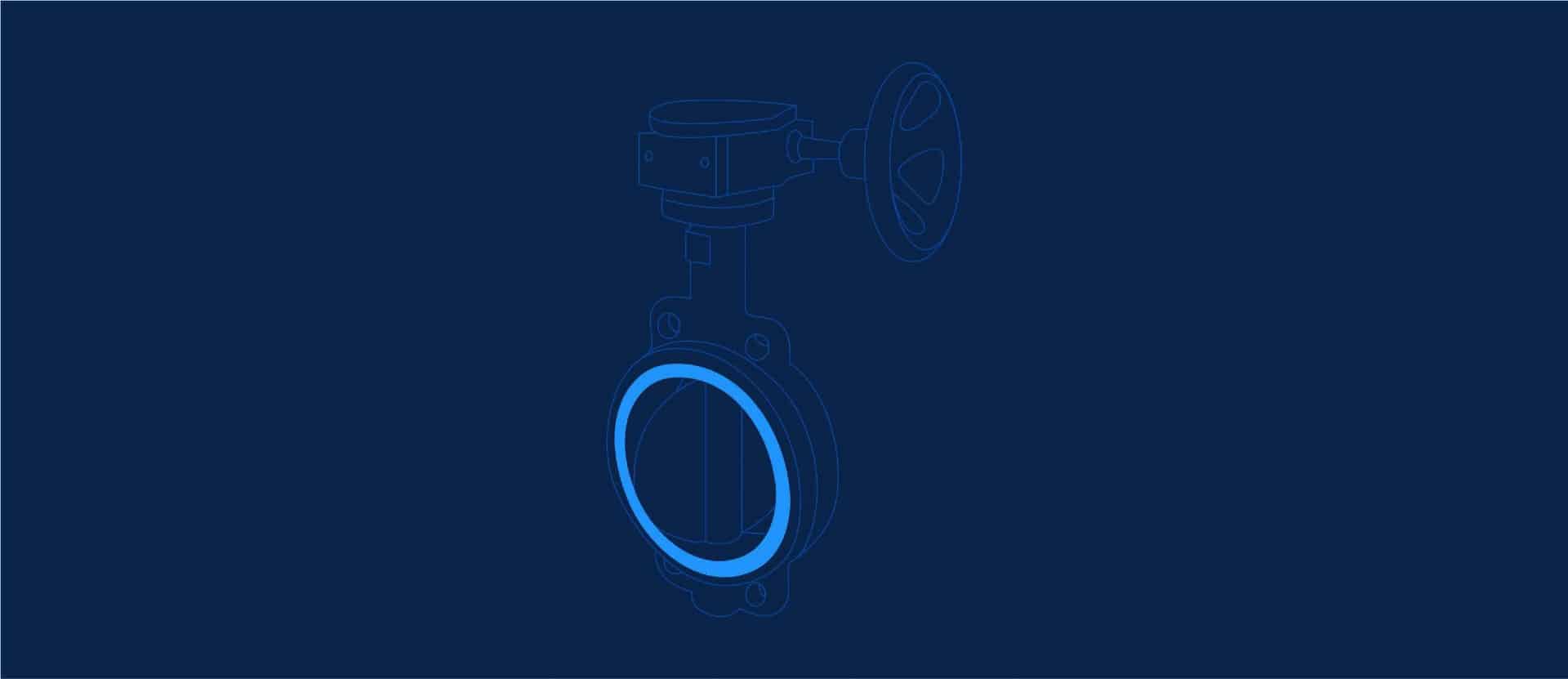

Butterfly Valves

Named for their resemblance to the wings of a butterfly, butterfly valves are similar to ball valves in that they are on/off quarter-turn valves. However, instead of a perforated ball, butterfly valves have a disc that vertically bisects the valve cavity. They are available in one- and two-piece designs; in the one-piece version, the disc will rotate on a vertical axis to allow media to pass. In the two-piece version, the halves of the disc fold toward each other (like a butterfly) to allow media to pass.

Like ball valves, butterfly valves can be actuated automatically or manually, via either a level or handwheel. Butterfly valves are not recommended for precise control applications.

Butterfly valves are generally considered more lightweight than ball valves, especially in larger sizes, since the disc imposes much less weight on a piping system than a solid ball of equal diameter. They are also considered less expensive than ball valves, since they require fewer parts.

When closed, the butterfly valve’s disc generally ensures a tight seal, but this becomes less reliable as pressure increases. The higher the media pressure, the more difficult it is to open the valve when closed, and the higher the pressure drop once the media begins to flow again. A bypass valve is sometimes required to alleviate this pressure, especially in larger diameter pipes.

Since the rotated or folded disc remains in the path of the media flow when the valve is open, butterfly valves impose a higher pressure drop than ball valves. Because of this obstruction, piping systems with butterfly valves do not lend themselves to pigging.

When to Use Butterfly Valves

Butterfly valves are popular in systems that process fluid media without solid particles. They are also favored in sanitary applications, since they do not trap media while in the “off” position (unlike ball valves). Three-piece butterfly valves (in which the center section can be removed) or those in tri-clamp connections are fairly easy to clean. Butterfly valves are found in the following industries and applications:

- Sewage & wastewater treatment

- Municipal water transport

- Chemical processing

- Agricultural processing & irrigation systems

- Food processing

- Beer & soda productionIf pressure drop (flow loss) does not pose a significant issue, butterfly valves are a cost-effective, lightweight solution for on/off media control.

How Are Ball Valves & Butterfly Valves Similar?

Ball valves and butterfly valves share a number of similarities. Both are:

- Quarter-turn rotary valves (turn 90° from fully closed to fully open)

- Relatively inexpensive

- Durable

- Reliable

- Simple to operate

- Ideal for accurate fluid handling

- Appropriate for commercial, industrial and residential applications

- Used to control media with a wide range of temperatures and pressures

- Controlled manually or automatically (via electric, pneumatic or hydraulic actuator)

How Are Ball Valves & Butterfly Valves Different?

While they may be suitable for many of the same applications, knowing the key differences between ball valves and butterfly valves can ensure your system operates at maximum efficiency.

Compared with ball valves, butterfly valves are:

- Lighter

- Relatively smaller

- Less expensive, especially at larger pipe sizes

- Prone to causing pressure drop, as the disc interferes with media flow

- More difficult to operate under high pressure

- Sometimes preferred in sanitary applications, since they do not trap media in the “off” position

Likewise, ball valves are:

Ball Valves vs. Butterfly Valves: Benefits & Drawbacks

For a different way of comparing the two, here are the qualities of ball valves and butterfly valves measured side-by-side.

| Ball Valve | Butterfly Valve | |

| Weight | Heavier at larger pipe diameters; may require support | Lighter relative weight, especially at larger pipe diameters |

| Size | Better suited for smaller pipe diameter (below DN 50, or 2”) | Suitable for larger pipe diameter (above DN 150, or 6”) due to lighter weight |

| Flow control | Suitable for ON/OFF control. Not recommended for flow control applications. | Suitable for ON/OFF control. Not recommended for flow control applications. |

| Flow regulation | Can be used for on/off control and proportional control when using a V-port ball; has better relative flow regulation than butterfly valves | Can be used for on/off control and proportional control |

| Flow restriction | Full port ball valves have no pressure drop | Disc restricts flow, creating a pressure drop |

| Installation space | Requires larger relative installation space | Requires smaller relative installation space |

| Seal | Provides a tight seal in process applications that require zero leakages when shut off | More prone to leakage at higher pressures |

| Connection style | Wide array of connection types with threads or flanges | Flanged, NPT and tri-clamp styles |

| Operating conditions | Suitable for use in high pressure applications (many models can be used up to 1000psi) certain seal materials can accommodate even higher pressure | Typically operates at a lower pressure |

| Port | Available in multi-port designs | Can only have two ports |

| Applications | -Fluid & gas media

-Slurries (some solid particles) -Oil & gas -Petroleum refining -Food & beverage -Automotive -Vehicle wash systems -Power processing -Pharmaceutical -Chemical admixtures & treatment -Irrigation & water treatment equipment -Manufacturing facilities -Residential plumbing |

-Water-based processes

-Sewage & wastewater treatment -Municipal water transport -Chemical processing -Agricultural processing & irrigation systems -Food processing -Beer & soda production |

Ball Valve or Butterfly Valve? Key Considerations

If you are not sure which valve would be best suited for your system, an experienced valve manufacturer can answer your questions and guide you toward the right solution.

There are exceptions to every rule, but in general, choose a ball valve if:

- Your application requires fast cycle times

- Your system generates up to 1,000 PSI of pressure

- Reliable, leak-tight seals are required

- You require a multi-port flow pattern

- You need a valve that can handle both liquid and gas media

- Your system is in frequent operation

- Your system requires pigging

- Your application is on the smaller side (pipes are less than 6” in diameter)

Choose a butterfly valve if:

- Your system generates 250 PSI of pressure or less

- You have a limited budget

- Your system cannot sustain heavy valves

- Pressure drop and leakage risk won’t cause a major issue

- Your process system is water-based

- Your system does not require pigging

Still not sure which to choose? Give Gemini Valve a call at 866-241-9801 or send us a message — we’ll be able to point you in the right direction.