Standard Port vs. Full Port Ball Valves: Benefits & More

Ball valves are popular for their reliable, air-tight flow shut-off and simple operation. Smaller, lighter and requiring less operating force than gate or globe valves, ball valves are available in a variety of designs and materials that provide flexibility, durability and ease-of-use.

Ball valves are favored across industries for piping systems involved in:

- Cooling

- Mixing

- Pneumatic circuits

- Processing

- Liquid filling

- And many more!

Although they are available in many different styles, all ball valves can be classified by the port (or bore) size — the size of the opening in the ball that the media flows through. Read on to learn more about when each port size is preferred.

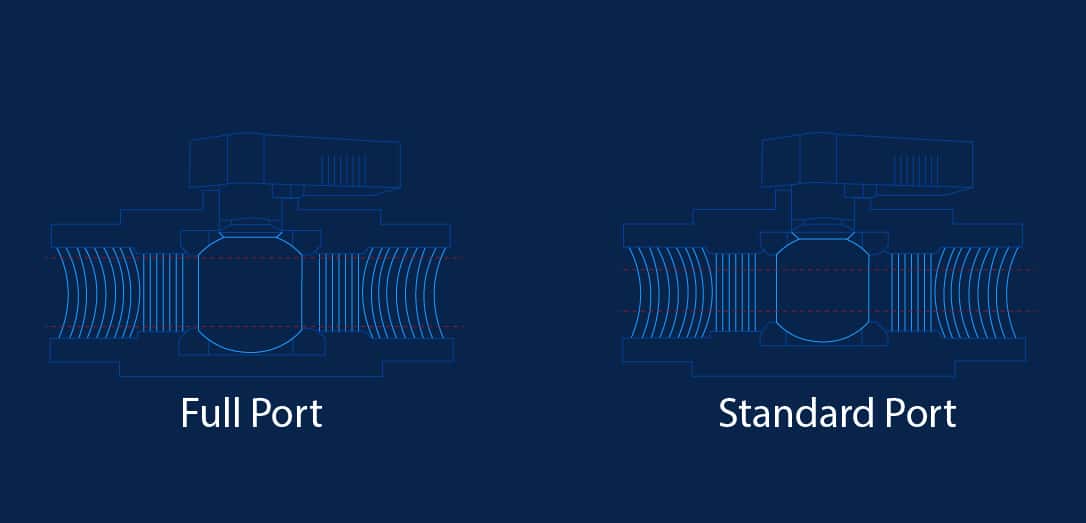

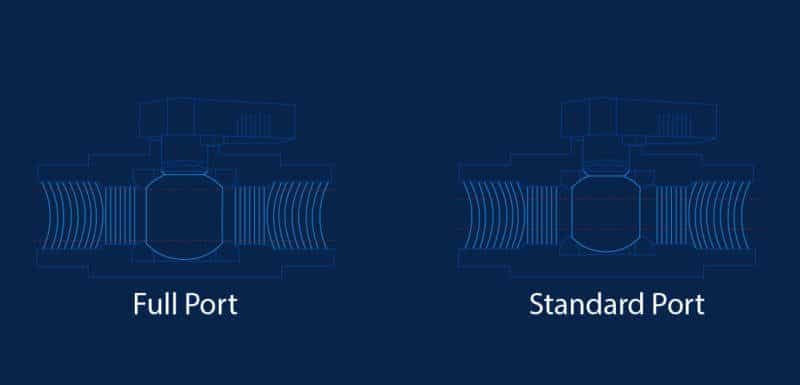

Standard Port vs. Full Port

Ball valve ports come in standard or full sizes. The difference can be summed up fairly simply:

Full port: The valve port is the same diameter as the pipe.

Standard port: The valve port is smaller than the pipe’s diameter. Exact port size varies but generally the port size is that of one pipe size smaller than the valve in question.

As always, there are benefits, drawbacks and appropriate applications for each.

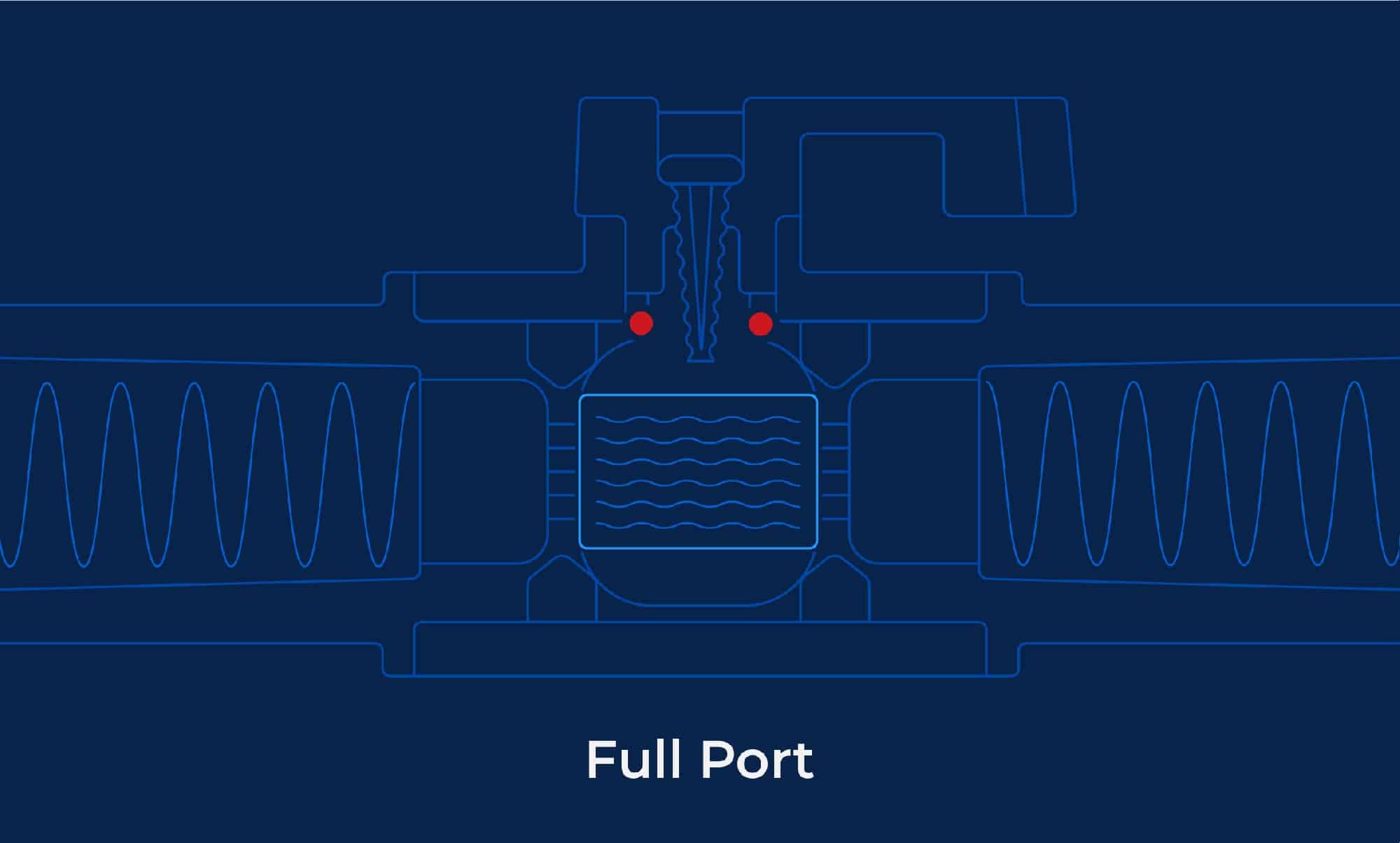

Full Port (Full Bore) Ball Valves

The straight flow path of a full port ball valve provides little to no resistance to the flow of liquid or gas, and thus creates very minimal pressure drop when fully open.

This ensures that the valve does not reduce flow rate and reduces the chance of cavitation, which is the formation of air bubbles caused by liquid pressure drop. Frequent or intense cavitation can erode or cause damage to a piping system over time.

That being said, when taking the entire application piping system into consideration, it is rare for the ball valve to be the bottleneck when it comes to flow rate. We will cover this in more detail later.

Standard Port Ball Valves

Because standard port ball valves have an opening that is typically one size smaller than the pipe diameter, they cause a larger pressure drop even when fully open. This is because media is constricted slightly as it passes through the valve, increasing the pressure and causing a potential cavitation risk in applications where the smaller port size may cause a rapid pressure drop.

Standard port ball valves are typically more economical than full port designs when considered for the same pipe size since they have smaller bodies that correspond to their narrower port. They are available in the same or lower pressure ratings compared to full port ball valves.

Are Other Valve Types Classified by Port Size?

The port size in other types of valves tends not to vary; gate and globe valves are almost always full port by design. This is more a result of their respective functions: Gate valves are simple open-and-close valves incorporating a flat “gate” or disc across the port, while globe valves can throttle media flow while forcing it to alter its path through the valve. There is not much use for different port sizes in these types of valves.

However, there are occasionally non-full port gate and globe valves, particularly in oil and gas industries, but these are not common.

When to Use Standard Port Ball Valves

Standard port ball valves are perfectly suited to most applications that call for ball valves. They are relatively compact, accomplishing their function while taking up less space and keeping costs down. If you require quick on-off function, simple operation, durability and a guaranteed leak-tight seal, any style of ball valve — full port or standard port — will deliver.

As long as a moderate pressure drop and slight flow turbulence are acceptable in your system, standard port ball valves are recommended.

In fact, changes in flow rate are normal in most piping systems; length of pipe sections, bends in the system or system conditions will affect the flow rate enough that a standard port valve will not be the most influential factor. In the vast majority of applications, the difference between a full port and standard port ball valve will have a negligible impact on the overall flow rate of the piping system.

When to Use Full Port Ball Valves

Full port ball valves will work in the same situations as standard ports but offer the added benefit of reducing pressure drop. This is especially important to note for applications in which maintaining flow rate is critical, and where the piping the media will travel through is relatively short with minimal changes in direction

Because they offer the least resistance to flow, full port ball valves are recommended for systems in which both solids and liquid flow through the valves. The open design reduces the possibility of build-up inside and around the valve connection, which can affect the overall performance of the valve over time.

If you have any questions about which port design might be best for your application, don’t hesitate to reach out to the Gemini Valve team. We are always happy to help.

Elevate Your Professional Insight on Valve Selection

Our comprehensive eBook provides a deep understanding of valve types, selection criteria and industry applications. Equip yourself with the best.