Flow Rate & CV Calculator for Valve Sizing

While knowing the pipe connection size and orifice diameter is necessary for valve sizing, calculating the media flow rate and pressure drop across the valve will give you more accurate sizing information.

What Is Flow Rate?

The valve flow coefficient, or flow rate, is the rate at which media flows through the valve, and how much the pressure of the flow changes (drops) across the valve. The state and viscosity of the media will have an effect on flow rate, as will the valve size, type and diameter of the pipe connections. The flow rate value can be determined using a formula; the larger the value, the higher the flow rate will be through the valve at a given pressure drop.

Flow rate is expressed as Cv or Kv, depending on the system of measurement being used (imperial or metric, respectively). The minimum required Cv value is often listed in a valve’s product description, or wherever its specifications are found.

Cv value = Flow coefficient in imperial units

Defined as:

-

-

-

-

-

- The flow rate in U.S. gallons per minute (gpm) of water

- At a temperature of 60° Fahrenheit

- With a pressure drop across the valve of 1 psi

-

-

-

-

If the desired flow rate, pressure drop, and media characteristics are known, the minimum required Cv value can be calculated. Different formulas are used for fluids and gases.

Valve Size Chart (Cv)

For a quick reference, here are the approximate Cv values (in psi) for a range of standard valve sizes.

| Approximate Cv Values (psi) | |||

| Valve Size (inches) | Single Piece Body Reduced Port | Two Piece Body Standard Port | Two Piece Body Full Port |

| ¼ & ⅜ | – | 5.5 | 8 |

| ½ | 5.5 | 8 | 12 |

| ¾ | 10 | 12 | 32 |

| 1 | 15.5 | 32 | 46 |

| 1 ¼ | 20 | 46 | 82 |

| 1 ½ | 37 | 82 | 120 |

| 2 | 60 | 120 | – |

Cv Value Calculator for Fluids

The Cv value for fluids can be found using the following formula:

Where:

Cv = Valve flow coefficient

Q = Volumetric flow rate (Gallons per minute, GPM)

P1 = Inlet Pressure (psia)

P2 = Outlet Pressure (psia)

SG = Specific Gravity of the fluid

Calculate the minimum Cv value of your valve below. Choose a valve with a Cv value equal to or higher than the calculated value to achieve the desired flow rate.

Warning: Flow rate calculations are extremely complex, this resource is intended for basic estimates only. Please also note that flow rate formulas are simply intended to calculate flow rate for the immediate area near the valve inlet and outlet. In most applications there are more significant elements within the piping system that impact the overall flow rate.

Cv Value Calculator for Gases

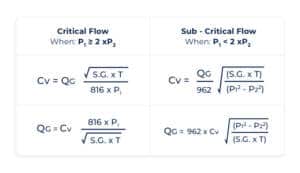

The flow coefficient formula is more complex for gases, since gases are compressible fluids and therefore affected by temperature. Two formulas are used to accurately estimate flow: the critical flow formula is used when the upstream pressure equals or exceeds two times the downstream pressure (also known as choked flow). The sub-critical flow is used if the upstream pressure is less than two times the downstream pressure.

The Cv value for gases can be found using the following formula:

Where:

Cv = Valve Flow Coefficient

QG = Gas Flow in Standard Cubic Feet per Hour

T = Absolute temperature in °R. (°F + 460)

psia = Absolute pressure. This is psig (gage pressure) plus 14.7 (atmospheric pressure)

S.G. = Specific Gravity of medium where air at 70°F and 14.7 psia = 1.0

P1 = Upstream (inlet) pressure in psia

P2 = Downstream (outlet) pressure in psia

Calculate the minimum Cv value of your valve below. Choose a valve with a Cv value equal to or higher than the calculated value to achieve the desired flow rate.

Valve Sizing 101: Your Blueprint for Effective Flow Management

Discover how strategic valve selection impacts flow control processes.