What Is Water Hammer? [Best Practices, Dangers & Tips]

![what-is-a-water-hammer-feature What Is Water Hammer? [Best Practices, Dangers & Tips]](https://www.geminivalve.com/wp-content/uploads/2021/05/what-is-a-water-hammer-feature-800x385.png)

Introduction: What Is Water Hammer?

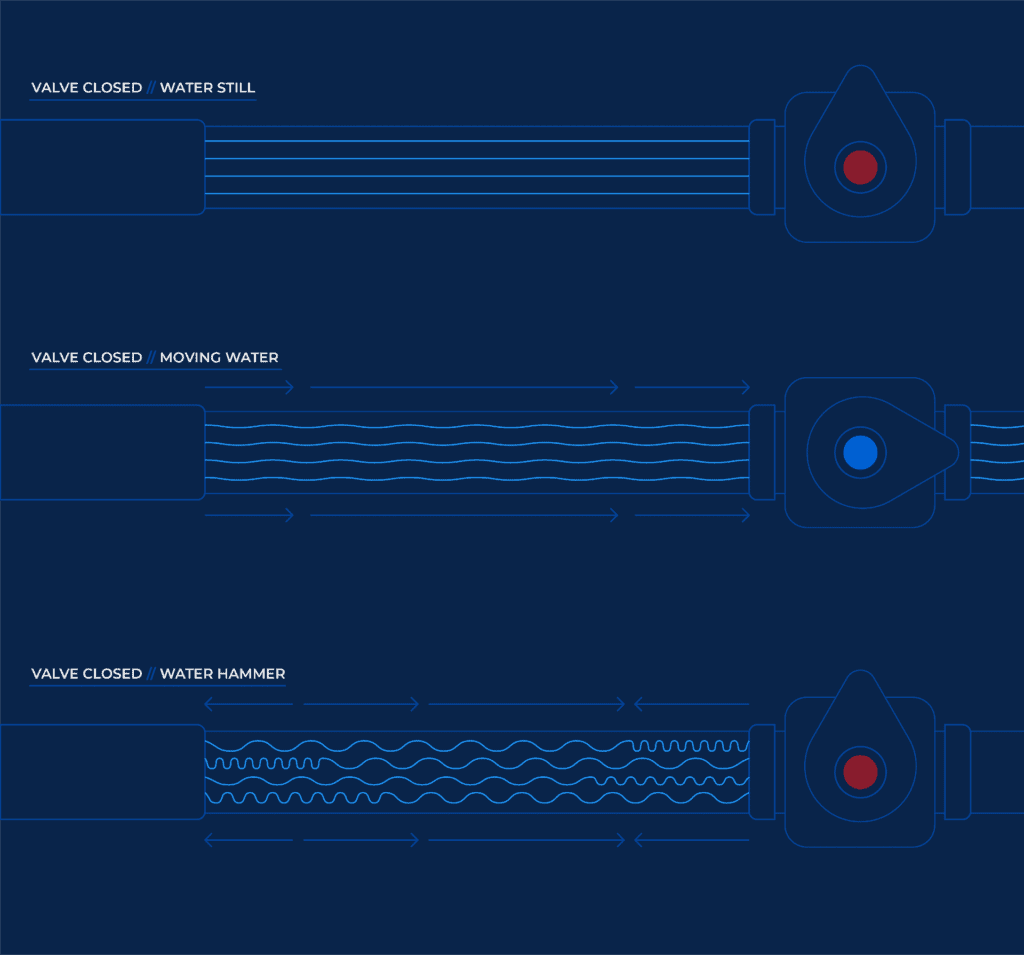

Water hammer is a pressure shock wave that occurs when fluid in a pipe is abruptly forced to stop or change direction by a closing valve. Also called hydraulic shock, the signs of water hammer include a loud thumping or “hammering” noise from pipes carrying fluid and moderate- to heavy vibrations along the pipe system. Its impact can range from mild or undetectable vibrations to severe and very disruptive pressure shocks.

Without mitigation from the proper kind of valve or pipe closure, water hammer can cause equipment damage and pose safety concerns in industrial settings. It can also cause leaks in the home and damage to residential appliances and property, especially if it goes untreated for a significant amount of time.

Common Causes of Water Hammer

Commercial Water Hammer

Water hammer on an industrial scale can be extremely hazardous to equipment, product and personnel, so it’s crucial that these scenarios are avoided in commercial settings:

- Piping systems without bends or loops: Systems that feature long lengths of pipe without directional variation can result in excessive fluid velocity, which worsens the effects of water hammer when it’s inevitably caused by a closing valve. Reconfiguring pipes so that fluid encounters bends and turns can reduce its velocity.

- Quick closing valves: Valves that utilize slamming “doors” or flaps activated by gravity or reverse flow can cause higher levels of pressure shock when suddenly closed.

- Improper closing of valves: System operators not trained in proper valve closing procedures can unwittingly cause water hammer. It’s critical that all personnel are trained in the safest standard workplace procedures for opening and closing valves.

- Not following proper startup or shutdown procedures: As with the routine opening and closing of valves, it’s imperative that any system operators or maintainers know how to start or shut down pipe systems. For example, valves that are closed out of order during shutdown procedures can cause extra pressure buildup, which can lead to a disastrous startup next shift.

Residential Water Hammer

Water hammer in a residential setting can be caused by:

- High water pressure: Water pressure in a residential home should not exceed 80 pounds per square inch (psi), although 60 psi is a comfortable ceiling. Anything higher than 80 psi increases the chances of water hammer as well as worsens the effects and can result in thousands of wasted gallons of water per month.

- Pipe systems without air chambers: Water hammer is typically caused when fluid comes to an abrupt halt and has nowhere to go but back the way it came. Air chambers or water hammer arrestors provide empty spaces that give interrupted fluid somewhere to divert into.

- Clogged or waterlogged air chambers: Even if a pipe system features air chambers, these can become clogged due to scale buildup, or simply flooded over time. It’s important to routinely check and clean any air chambers or similar attachments.

The Dangers of Water Hammer

Industrial Water Hammer Risks

Industrial pipe systems often carry large volumes of fluid at rapid speeds, so any disruption to this flow can have significant consequences. High-pressure vibrations can cause damage to both pipes and their support systems, plus can erode pipe joints, valves, gauges and other system components. Leaks caused by eroded joints can damage property and inventory and result in costly downtime. In the worst-case scenarios, extremely hot or toxic fluid can cause employee injury, as can dislodged pipes or blown gaskets.

Residential Water Hammer Risks

Water hammer can burst pipes and cause leaks, which can result in costly repairs and damage to personal possessions such as appliances and furniture. Injury can also be caused by falling or bursting pipes.

Use These Tips To Avoid Water Hammer

Commercial Water Hammer Prevention

Proper system design can greatly reduce the severity of water hammer and water hammer damage, if not prevent it altogether. Industrial facilities can reduce fluid velocity by shortening pipe lengths and adding elbows and loops to their pipe systems, which forces fluid to slow down as it encounters turns. Pumps can also be programmed to gradually increase or decrease fluid pressure. If a valve needs to close, system operators can first reduce fluid velocity to ensure any disruptions to flow won’t cause excessive shock.

Workplace training goes a long way in preventing or mitigating water hammer damage. Every training process should include teaching system operators the correct way to open and close valves, how to properly conduct startup and shutdown procedures and how to predict, detect and react to water hammer.

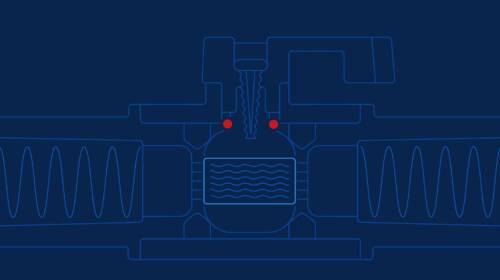

If a pipe system redesign is not feasible, commercial facilities can install water hammer arrestors at the pipe joints most likely to experience hydraulic shock. Water hammer arrestors are external components that can be fitted between pipe joints. When a valve suddenly closes, fast-moving fluid with nowhere to go can bang and shudder inside a pipe, sometimes with disastrous results. With a water hammer arrestor, that fluid now has somewhere to go instead of back the way it came, and any shock caused by sudden stoppage is absorbed by a moveable piston inside an air-filled chamber.

Residential Water Hammer Prevention

To prevent water hammer in the home, homeowners can install pressure-reducing valves like ball valves or rotary valves in their pipe systems. Air chambers can also help reduce pressure shock waves — like water hammer arrestors, these are external components that can be fitted between pipe actions at a perpendicular angle and give moving fluid somewhere to go when it encounters a sudden disruption.

It’s generally best practice to secure any loose pipes in the home, since even mild vibrations can cause unsecured pipes to become dislodged from their supports or damage nearby objects. Once a loose, noisy pipe is secured, homeowners may find that their water hammer issue isn’t nearly as severe as they may have thought. If the noise and vibrations caused by fluid disruptions persists, however, other treatments like installing air chambers or pressure-reducing valves are recommended.

Valves That Are Prone to Causing Water Hammer

There are certain types of valves that are more likely to cause hydraulic shock. Due to their design, the following types of valves are prone to rapidly opening and closing (or slamming), and therefore more likely to cause pressure shocks.

- Solenoid valves

- Check valves

- Pneumatically actuated on/off valves such as ball valves or butterfly valves

Valves to Prevent Water Hammer

- Non-slam check valves function similarly to normal check valves but are designed to close without slamming.

- Electrically actuated valves typically cycle more slowly than pneumatically actuated valves, and are therefore less prone to causing water hammer.

Water Hammer Prevention Equipment

There are several accessories or components that can mitigate water hammer if a pipe system redesign is not possible.

- Water hammer arrestors, mentioned previously, are external attachments that feature an air chamber fitted with a sliding piston, which can absorb pressure shock while being cushioned by the air in the chamber beyond.

- Silent or non-slam check valves close when the differential pressure across the closure decreases, rather than closing from reverse flow like swing or tilting disc check valves. Non-slam check valves allow fluid flow to decelerate, which decreases fluid momentum before the valve is fully shut and prevents reverse flow. This type of valve is recommended in vertical pipe lines, since valves that rely on gravity are less effective here.

- Water pressure regulators can ensure that fluid pressure does not exceed 60 psi. This is especially important for residential properties, where water pressure should fall between 40 and 60 psi.

Flashing vs. Water Hammer

Flashing is a phenomenon specific to steam systems, although it is similar to water hammer. It occurs when steam condenses into liquid and accumulates inside piping, then rapidly vaporizes due to rising temperature, thereby increasing the pressure inside the pipes. The results can mimic those of water hammer, ranging from mild vibrations to thunderous banging and even pipe system collapse.

Calculating Water Hammer Pressure

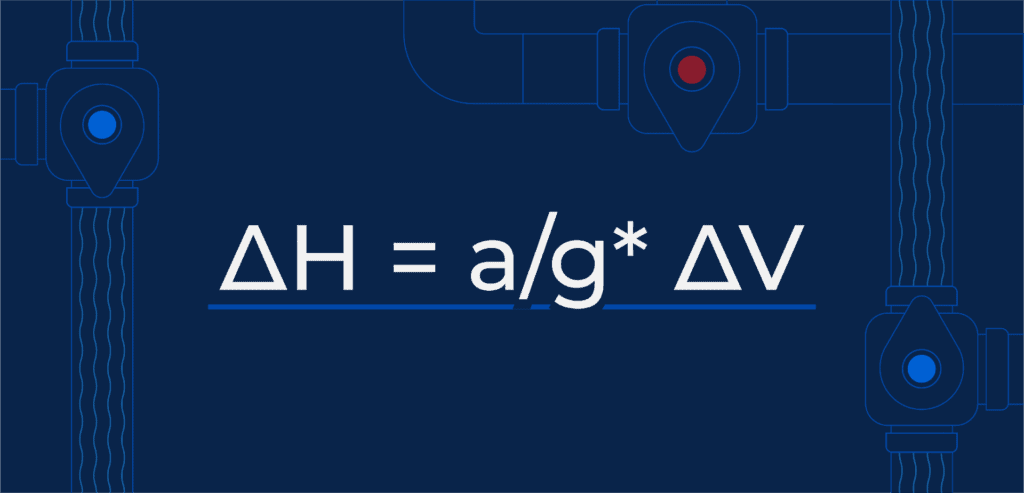

The first step in water hammer prevention is to calculate its likelihood. Whether in a commercial or residential setting, you can calculate the potential pressure of water hammer by measuring the standard pressure of fluid flowing through your pipe system. Once you have this information, water hammer pressure can be calculated using this equation:

∆H is the change in head pressure

∆V is the change in fluid flow velocity

a = acoustic velocity in the media

g = gravitational constant

Ex.:

a = 4864 feet per second

g = 32.2 feet per second

∆V = 5 feet per second

∆H would be 756 feet (328 psi)

Key Piping Design Considerations

When installing or reconfiguring a pipe system, there are some preventative measures system designers can take to decrease the likelihood of water hammer.

- Install air chambers or water hammer arrestors at pipe joints.

- Incorporate elbows and loops into the piping system to force fluid to slow down as it navigates turns.

- Secure all pipes in place to prevent noise or damage caused by vibrations.

- Utilize electrically actuated valves for their slower cycle time.

- Don’t mix metals when installing or repairing pipes, since different metals can contract or expand at different speeds and temperatures. Conflicting expansion or contraction can result in an unwanted buildup of pressure and can hasten the occurrence of leaks due to vibrating pipes.

Valve Sizing 101: Your Blueprint for Effective Flow Management

Discover how strategic valve selection impacts flow control processes.