DN to NPS Pipe Size Chart [In MM & Inches] Explained

When selecting a valve, you’ll need to know what pipe size is needed for the piping in your application. Pipes are sized according to two measurement designations: DN and NPS. Since these classifications are based on two different systems of measurement, a DN to NPS conversion chart is a must-have for piping system design.

What Do DN and NPS Stand For?

DN stands for diametre nominal, which denotes the size of a pipe (specifically, its inside diameter) in millimeters (mm). NPS, or nominal pipe size, is merely the non-metric equivalent in which the diameter is measured in inches (in.). In print, pipe size designations are not followed by an abbreviation of the unit of measurement. For example, a pipe’s diameter might appear as DN 20, or NPS ¾.

DN measurements conform to the International Organization for Standardization (ISO) metric standards for all piping in plumbing, natural gas, heating oil and other miscellaneous piping. NPS is used to measure pipes, valves, pipe fitting and other components of piping systems, and conforms to the American Society of Mechanical Engineers (ASME) standards. The acronym “NPS” is often confused with the acronym for national pipe straight, which refers to the standard that governs pipe thread structure and shape.

How Are Pipe Sizes Measured?

When measured with an accurate ruler, a pipe’s exact diameter might not exactly conform to any DN or NPS size classification. This is because pipes are named and classified based on their “nominal” or “trade” names to simplify things; for example, a pipe with an NPS 3 classification might have an inside diameter measuring 3 ⅝ inches.

If a pipe is unmarked, or you’re not sure of its size, you can determine this using some simple tools.

To measure a male pipe fitting, you’ll need a piece of string, a ruler, and a calculator.

-

-

- Wrap the string around the pipe and mark the point of contact.

- Using the ruler, straighten the string and measure from the end of the string to the point of contact.

- Divide this measurement by 3.1459 ().

- Consult a pipe sizing chart to determine the nearest DN or NPS value.

-

Finding the size of a female pipe fitting is much simpler, and only requires a ruler and a calculator.

-

-

- Measure the inside diameter of the pipe across the opening.

- Consult a pipe sizing chart to determine the nearest DN or NPS value.

-

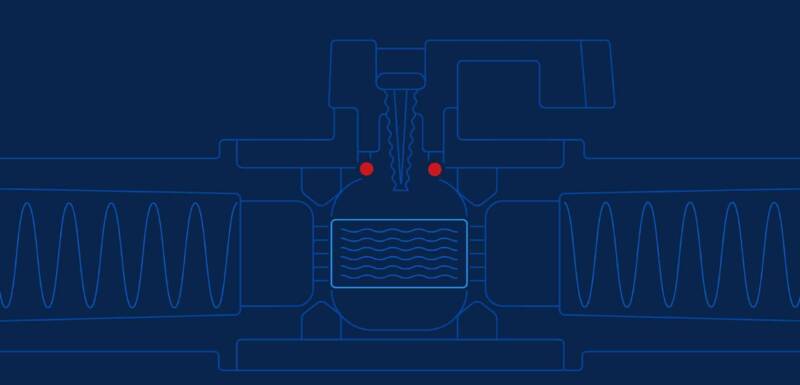

Once you know the size classification of your pipes, you will know which size valves you might need. Valve sizes directly correlate to the diameter of the pipe in which they are placed. However, there are two different size classifications for valves.

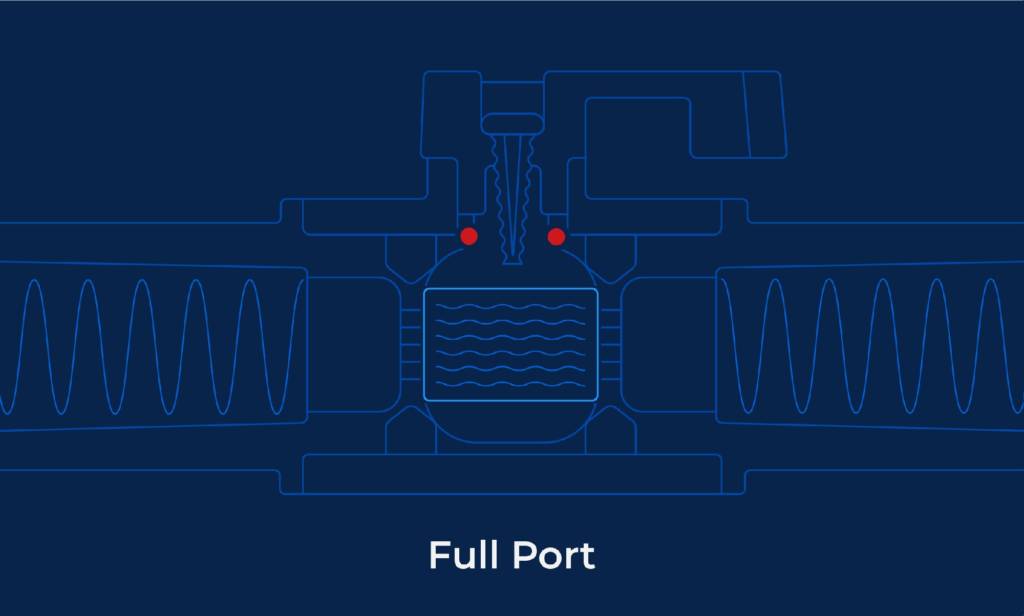

Full port (or full bore) valves have a port, or hole, whose diameter matches that of the pipe it’s in. For example, a 1 ¼” full port ball valve is meant for a NPS 1 ¼ pipe.

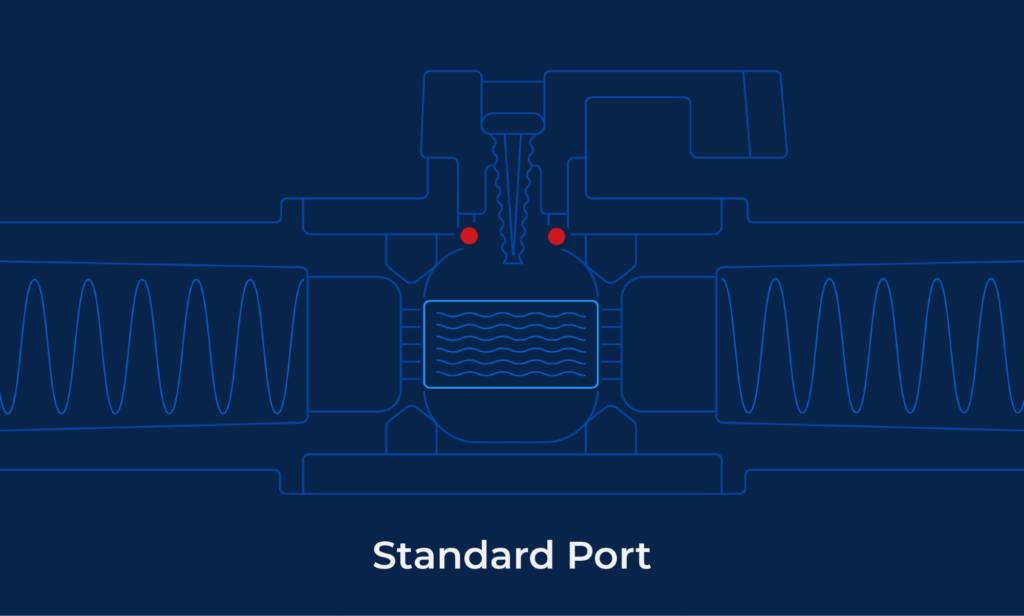

Standard port (or standard bore) valves are meant to fit in the next-smallest pipe size. This means that a ½” standard port ball valve is designed to fit in an NPS ¾ pipe.

How to Choose the Right Valve

Full port valves have low flow resistance, and therefore can act as just another stretch of pipe when fully open. When fully open, a full port valve will cause little to no pressure drop, which is the difference in media pressure on either side of the valve. Full port valves are required for applications in which flow rate and pressure drop are critical considerations and are especially preferred for more viscous media. They are the best choice for isolating media in a piping system, and most allow for two-way flow.

Since standard port valves have holes that are slightly narrower than the pipes they’re in, they offer a bit more resistance to media flowing through the valve. In a fully open position, standard port valves will cause a pressure drop. Standard port valves are the default choice for most applications and easy-flowing media, especially if space is limited, and are more economical than full port valves.

Although standard port valves do restrict flow, valve port sizes are not typically a major cause of bottleneck in a piping system; rather, flow rate is usually dictated by the length of a pipe and the number of bends in the piping system.

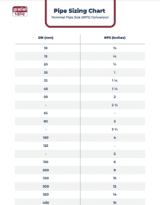

Pipe Sizing Chart

Download or print this chart for easy access to DN and NPS conversions.

| Nominal Pipe Size (NPS) Conversion | |

| DN

(mm) |

NPS

(inches) |

| 10 | ⅜ |

| 15 | ½ |

| 20 | ¾ |

| 25 | 1 |

| 32 | 1 ¼ |

| 40 | 1 ½ |

| 50 | 2 |

| – | 2 ½ |

| 65 | – |

| 80 | 3 |

| – | 3 ½ |

| 100 | 4 |

| 125 | – |

| – | 5 |

| 150 | 6 |

| 200 | 8 |

| 250 | 10 |

| 300 | 12 |

| 350 | 14 |

| 400 | 16 |

| 450 | 18 |

| 500 | 20 |

| 600 | 24 |

| 700 | 28 |

| 800 | 32 |

| 900 | 36 |

| 1000 | 40 |

| 1200 | 48 |

If you have any questions about pipe sizing, or need guidance in choosing the right ball valve size for your application, the team at Gemini Valve is happy to help. Send us a note today, and we’ll be in touch soon.

DN to NPS Pipe Size Chart [In MM & Inches] Resource

This chart will help you convert your measurements to the correct pipe size.