What is a Ball Valve? Parts, Actuation, Diagrams & More

What do household main water lines, fast food fryers and chemical processing all have in common? Ball valves! These compact, powerful valves are the catalyst for many essential processes. Read on to see our ball valve diagrams and an overview of the different parts and types available.

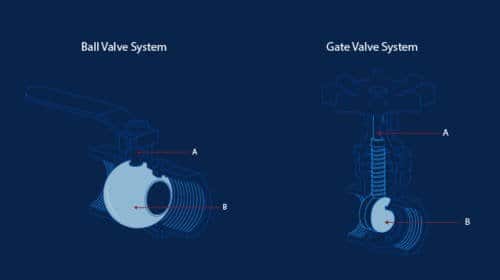

What is a Ball Valve?

Ball valves are quarter-turn on/off devices. A pivoting ball in the center of the valve controls the flow of liquid or gas media.

The pivoting ball is known as a rotary ball, and it is designed with a hole (a bore) in the center. A stem on the top of the ball rotates the ball to open or close the valve. The stem can be turned using manual levers or automation.

Ball valves are most commonly made of materials including steel, iron, brass, bronze or PVC.

How Does a Ball Valve Work?

Ball valves can have multiple ports, which are the openings in the valve. Two-way ball valves have two ports and are used for traditional on/off control. Multi-port valves (3-way, 4-way, etc.) are used in applications that require more than one source of media or that need to divert media in different directions.

The port of a ball valve can be opened or closed to control media either manually or through actuation. The manual option requires handles or levers and an operator to control the valve. Electric, hydraulic and pneumatic actuation don’t require an operator to control the valve. Actuation is ideal for complex control systems or those that are in remote areas that an operator cannot easily access.

Benefits of Ball Valves

Compared to other types of valves, ball valve offer several notable advantages:

- Compact, economical designs

- Fast shut-off speeds

- Durable in high-pressure, high-volume and high-temperature applications

- Less prone to corrosion or damage

- Long service life

- Versatile and ideal for a range of industrial applications

Applications That Use Ball Valves

Ball valves are used everywhere from around the home to specialized industries. Here’s a look at a few examples:

Home applications:

- Washing Machines

- Outdoor Hoses

- Dishwashers

Specialized industries:

- Oil & Gas

- Food & Beverage Equipment

- Automotive

- Vehicle Wash Systems

- Power Processing

- Pharmaceutical

- Chemical Admixtures & Treatment

- Irrigation & Water Treatment Equipment

- Manufacturing Facilities

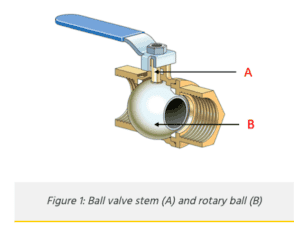

Parts of a Ball Valve

Ball valves are constructed with several crucial components:

- Valve Body

This is the main part of the valve and contains all of the components for on/off control. - Rotary Ball

The ball is designed with a center bore (hole) that the media flows through. The direction of the ball is controlled by turning the stem. - Stem

This connects the ball to the external control mechanism. For example, in a manual ball valve the stem is connected to a handle or lever. - Seats

These are discs that lie in between the body and the ball. Seats provide a seal between the two and also support the ball. - Power Source

The stem of the ball valve is rotated using manual or actuated power sources. Manual actuation includes levers and handles that are controlled by an operator. Automated power sources like electric, pneumatic and hydraulic actuation are also available. - Packing

This is a seal around the stem that prevents the media from escaping. - Bonnet

The bonnet is the part of the body that contains the stem and packing.

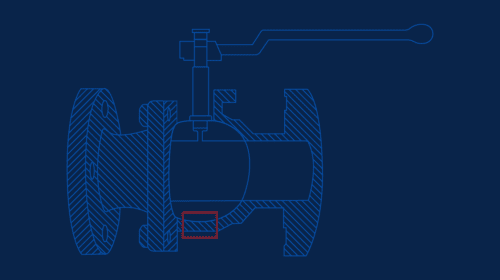

Valve Body Construction

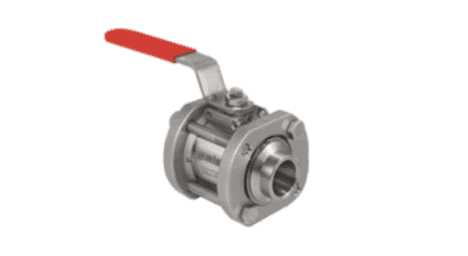

- 1-Piece Ball Valves

This design features a single, solid cast body. Since 1-piece ball valves are not designed to be easily repaired, these are often considered “throwaway” valves.

- 2-Piece Ball Valves This design consists of the main body and one end connection. Two-piece ball valves can be repaired if removed from service. However, repairs can be difficult because galling can occur in the threads when the end plug is removed from the valve body.

- 3-Piece Ball Valves

A 3-piece ball valve features a main body and two pipe connectors, which are threaded or welded to a pipe. The main body can be easily removed for cleaning or repairs, without removing the pipe connectors.

Valve Body Styles

There are three different types of valve body styles, as defined by Piping Guide:

- Split-Body Ball Valve

This design features a two-part body that is held together by a flange connection. One body part is smaller than the other, and the ball is inserted into the larger part. - Top-Entry Ball Valve

Top-entry designs allow you to remove the top of the valve to access the interior for assembly, disassembly, repair and maintenance. - End-Entry Ball Valves

These ball valves have a single main body, and the ball is inserted through one end.

Ball Designs

There are two main types of ball designs: floating and trunnion. Floating is the most common design, while trunnion balls are often more expensive.

Floating balls are supported by cupped seats to create a tight seal between the body and the ball. Trunnion balls work similarly to floating balls, only the seats are spring loaded and the ball only rotates on its axis. The operating torque is generally lower for trunnion valves.

Ball Valve Hole Designs

The hole in the ball can be designed using three different profiles:

- Full Bore

A full bore design is also called a full port design. The bore diameter is the same diameter as the pipe, which reduces friction losses and makes the valve easier to clean. - Reduce Bore

A reduced bore design is what you will find in most ball valves. This design has a smaller diameter than a full bore and may introduce small losses of friction. - V-Shaped

The hole in the ball or the valve seat can also have a V-shaped design. V-shaped bores can more precisely control flow rate when rotating the ball. - Vented

A vented ball valve has a small hole drilled into the upstream side. This hole eliminates unwanted pressure within the valve.

End Connections

There are two common ways to connect a ball valve to a piping system:

- Threaded

Threaded end connections can either be female or male. A female threaded end connection on a ball valve will fit with a male threaded pipe, and vice versa. There are also ball valves that come with one female and one male end connection. - Flanged

Flanged ball valves have bolt holes on the end connectors to attach to the matching flanges on a pipe.

Types of Actuation

Ball valves are powered manually or through automated energy sources.

- Manual Ball Valves

These are designed with handles or levers that must be controlled by an operator. This option is not intended for high-cycle applications. - Pneumatic Actuation

Pneumatic ball valves require compressed air as a power source. This option is best for applications that require high durability and fast cycling times. - Electric Actuation

Applications without access to compressed air rely on electric actuators, which are also known as motorized ball valves. This option is best for low cycle speeds. - Hydraulic Actuation

Hydraulic actuators are similar to pneumatic, but use pressurized fluid (water or oil) instead of air. This option provides more torque output than others.