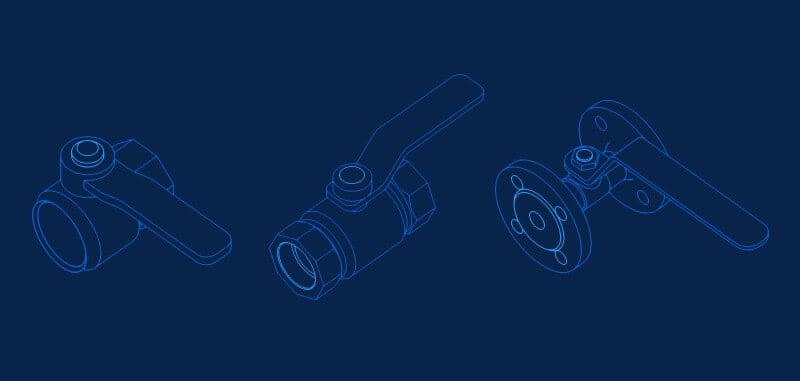

One- vs. 2- vs. 3-Piece Ball Valves: Construction & Applications

Chosen for their durability and reliability, ball valves provide on/off control for fluid or gas media. Ball valves appear in many industrial and commercial processing systems, and there are product variations that can accommodate almost any application. Several of these variations involve the number of pieces that make up the valve body design, which affects the upfront cost and capacity for maintenance.

What is a 1-Piece Ball Valve?

A 1-piece ball valve consists of a single, solid body with two openings, threads for screw-in connection and a manual handle or actuator for operation. One-piece ball valves are not designed to be repaired, so they must be replaced when damaged or corroded — hence the moniker “throwaway valves.” They are compact, economical, lightweight and reliable, since they present few opportunities for leakage.

One-piece ball valves are typically offered only in reduced port sizes, meaning the port size of the ball valve is smaller than that of the pipe size. For applications where flow rate is a critical consideration, 1-piece ball valves may not be the best choice.

What is a 2-Piece Ball Valve?

Two-piece ball valves feature a main body with a single threaded end connection and a lever. They are also available with a bolt and flange connection assembly, as well as with larger port sizes.

Like 1-piece ball valves, 2-piece ball valves are not designed to be repaired, since removing them once they are screwed in can cause galling on the threads (wear due to adhesion). Furthermore, the NPT connection is designed to be screwed in once and properly torqued to create a metal-to-metal seal within the valve body. Unscrewing this connection disrupts this seal and is not recommended.

Two-piece ball valves provide bidirectional flow shutoff and are available in full port configurations for applications where flow rate is critical. They are compact, reliable and economical, if slightly more expensive to replace than 1-piece ball valves.

What is a 3-Piece Ball Valve?

A 3-piece ball valve consists of a main body and two pipe connectors, one at each port. The connectors are typically either threaded, welded or flanged to a pipe, which allows only the valve body to be removed for cleaning and repairs. Both metal and elastomeric components can be easily replaced, including the ball, ball seat, stem and seals.

While three-piece ball valves carry a higher cost up front than those with fewer pieces, they are often the more cost-effective option in the long term. They can remain in service for their intended lifespan, sometimes longer, and replacing the components is far less expensive than replacing the entire valve. Additionally, the ability for the connectors to remain in place during maintenance prevents a line shutdown, so production can continue as needed.

Three-piece ball valves are available with full port and standard port options and are favored for applications in which frequent maintenance is necessary.

When to Use 1-Piece & 2-Piece Ball Valves

One- and 2-piece ball valves are the most common types of ball valves used across industries, wherever on/off fluid control is required. An exhaustive list of applications would be pages long, but common use cases include processing plants in the food, automotive, chemical, pharmaceutical and agricultural industries.

While either type of ball valve is adequate for many applications, neither 1- nor 2-piece ball valves should be used in high-cycle or high-pressure systems that require frequent maintenance. One-piece ball valves are not designed to be repaired, and, while it is possible, attempting to repair and reinstall a 2-piece ball valve is not recommended.

When to Use a 3-Piece Ball Valve

When properly maintained, the 3-piece ball valve is the most durable option of these product variations. The 3-piece ball valve is ideal for high-cycle, high-pressure applications that experience a great deal of wear and tear. Most notably, 3-piece ball valves offer the ability to remove components for cleaning or repairs, sometimes while the valve body is still in place. This means that easily worn elastomeric components like seals can be changed or replaced based on changing system conditions or age.

Three-piece ball valves are available with multiple connection types, including Female National Pipe Taper (FNPT), socket weld and tube socket weld. Exclusive to Gemini Valve, our 3-piece ball valves feature:

- Assembly bolts that can screw directly into the assembly flanges

- Lower chance of dropping or losing assembly nuts when installing or servicing the valve

- Two-piece pipe adapters that allow flanges to rotate independently of pipe connectors for much easier alignment

- Quick and accurate alignment to the valve center section

- Self-wear compensating stem seal design to ensure long, leak-tight service

These valves are found in many manufacturing and processing plants, especially those with extreme conditions, and are the preferred choice for vacuum applications.

1-Piece, 2-Piece & 3-Piece Ball Valve Comparison

| 1-Piece Ball Valves | 2-Piece Ball Valves | 3-Piece Ball Valves | |

| Benefits |

|

|

|

| Drawbacks |

|

|

|

Have questions about the best type of ball valve for your application? With over 50 years of experience in the ball valve industry, the team at Gemini Valve can recommend the ideal solution for your system. Give us a call or send us a message today, and we’ll be happy to help.