BSP vs. NPT Fittings: Which Seal Do You Need?

Industrial pressure piping systems use different types of pipe threads depending on the size of the system, the surrounding environment and the geographical area. Much like the metric and imperial systems of measurement, there are regional standards and preferences depending on the industry.

Pipe threads are governed by two sets of standards: National Pipe Thread (NPT) and British Standard Pipe (BSP). These standards stipulate the types of screw threads used to connect and seal pipe fittings together.

A Brief History of Pipe Fitting Standards

From the late 1700s to the mid-1800s, the Industrial Revolution was a catalyst for establishing standards across industries. Traditional modes of production transitioned to new, largely mechanized methods of manufacturing, which required new regulations. As parts were fabricated and shipped across continents and oceans, a standard for screw threads became necessary to avoid incompatible parts.

In 1841, British engineer Joseph Whitworth created a thread design that was adopted by many British railroad companies and quickly became the standard for all screw threads in the United Kingdom. At the time, it was known as the British Standard Whitworth system.

Whitworth’s standard was widely used in the U.K. and U.S. through the 1860s, but was not universally accepted. In 1864, American engineer William Sellers presented his own thread design to put an end to widespread incompatibility between American manufacturers. Once Sellers’ threads were used for railroad work done under government contracts, his design became the U.S. standard for screw threads.

Today, we have Whitworth and Sellers to thank for the BSP and NPT pipe thread standards, respectively. The geographical origin of a piping system or parts still dictates the thread standard used; U.S.-based manufacturers standardize their threads to the NPT standards, while Britain and most of the rest of the world adhere to the BSP standards.

The Importance of Pipe Threads

Threaded pipe connections provide tight seals for systems carrying liquids, gases and steam. Threads are found on the ends of pipes and on fittings like couplings, elbows and tees and can be made of steel, brass, bronze, cast iron and plastics like nylon and PVC.

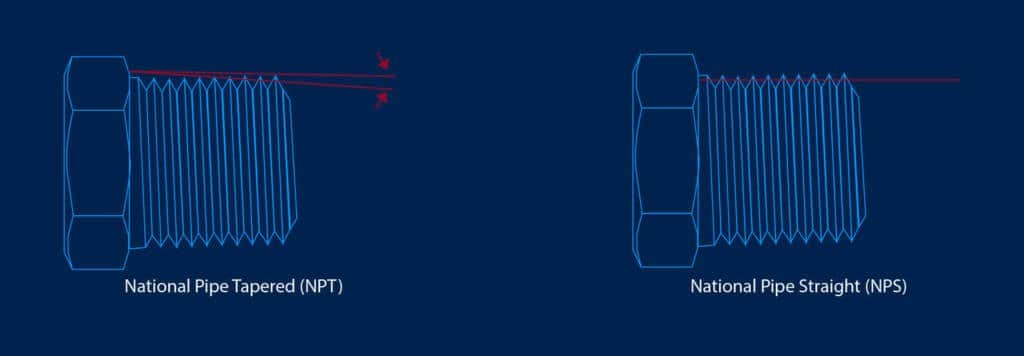

Threaded connections are categorized as either straight (or parallel) or tapered, in which one end of the threaded connection is narrower than the other. Tapered pipe connections are favored in a wide variety of industries, including power plants, chemical, oil and gas, manufacturing and shipping.

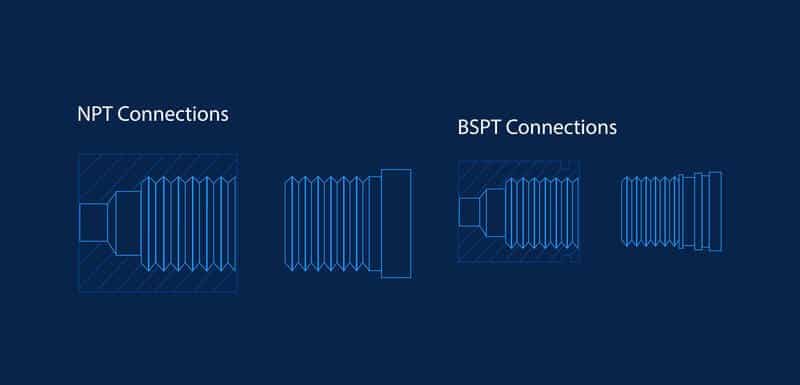

The NPT standards are divided into two categories: National Pipe Tapered (also NPT) and National Pipe Straight (NPS). Likewise, BSP standards are separated by tapered (BSPT) and parallel (BSPP).

What is an NPT Thread?

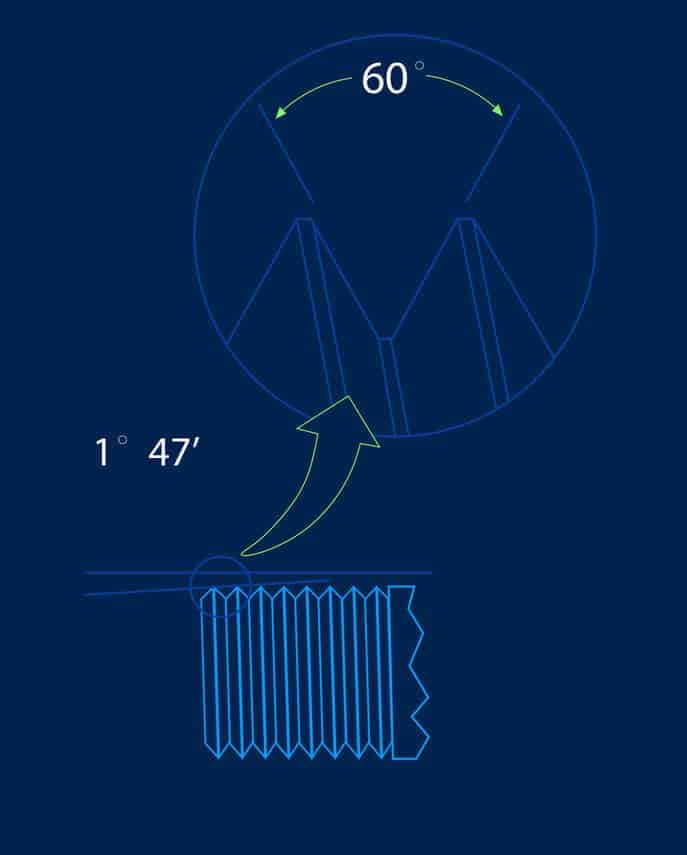

Per William Sellers’ original design, NPT threads are separated at a 60 degree angle and have flattened peaks and valleys. Connections can either be the same dimensions all the way along the thread (straight), or tapered toward the tip.

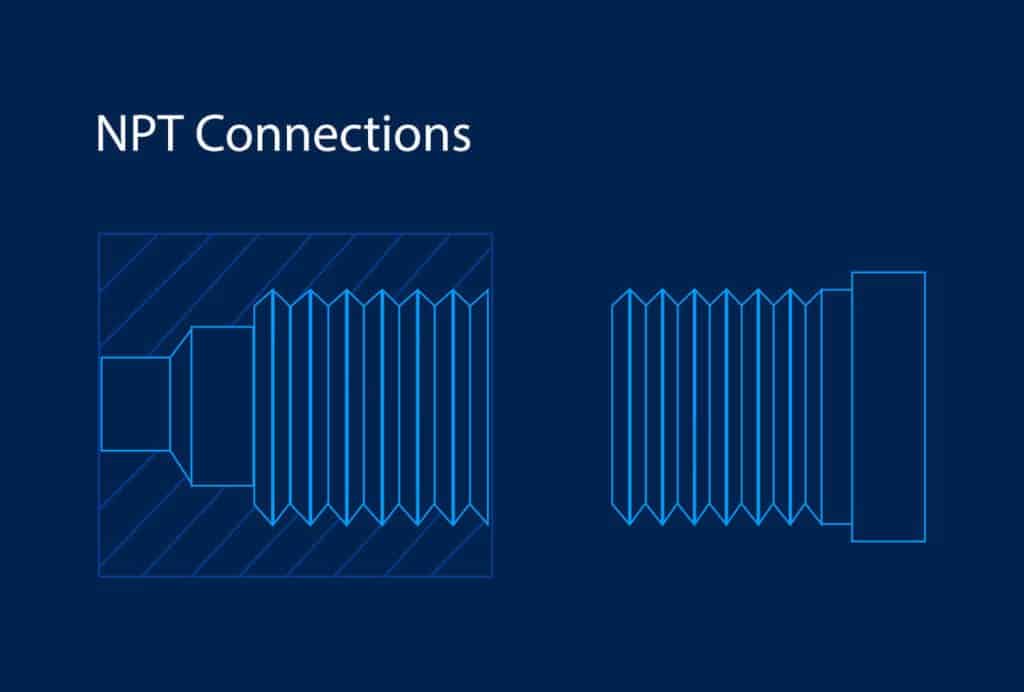

NPT tapered threads are the most common type of thread for pressure systems in the U.S. and Canada. Tapered threads are favored because they create a better seal, which is especially crucial in high pressure applications.

In tapered connections, the male fitting (MNPT) has a thread that locks into the female fitting (FNPT), then stretches the female fitting until the amount of force between the two can withstand pressure from media traveling through the pipes.

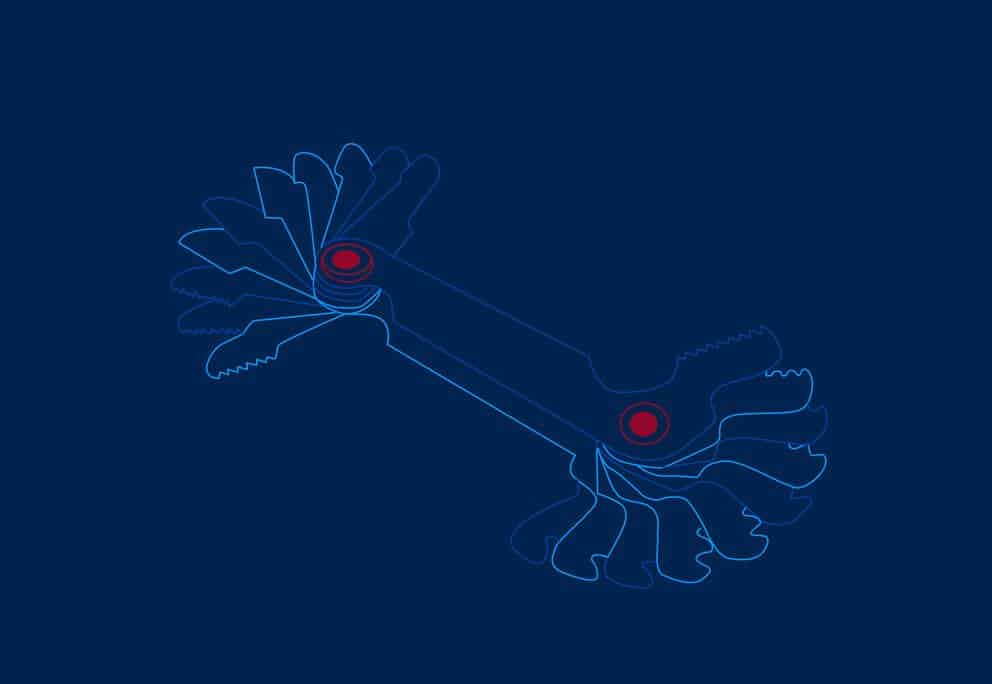

One challenge of the tapered thread design is that over-tightening or poor lubrication can lead to galling, or wear caused by friction between two surfaces. Therefore, it’s important to use lubrication like petroleum jelly or silicone spray.

Thread sealant is also needed to make connections leak-tight, but be careful not to overtighten the connection as this can cause media to leak around the sealant.

What is an NPS Thread?

NPS, or National Pipe Straight threads, have the same characteristics as Sellers’ tapered threads except that they maintain the same diameter from the shoulder (base) to the tip. Straight pipe threads need an O-ring or a gasket to create a tight seal. Although it is possible to achieve an effective seal when mixing NPT tapered and NPS connections, the two are not considered compatible and may result in leaks from the pipe joint.

Though NPS threads do not provide as tight a seal as tapered threads, they are frequently used for connecting two surfaces of varying thicknesses. Straight thread connections allow a nut to move freely up and down the connection, whereas tapered threads lock tightly once they are in place.

What is a BSPT Thread?

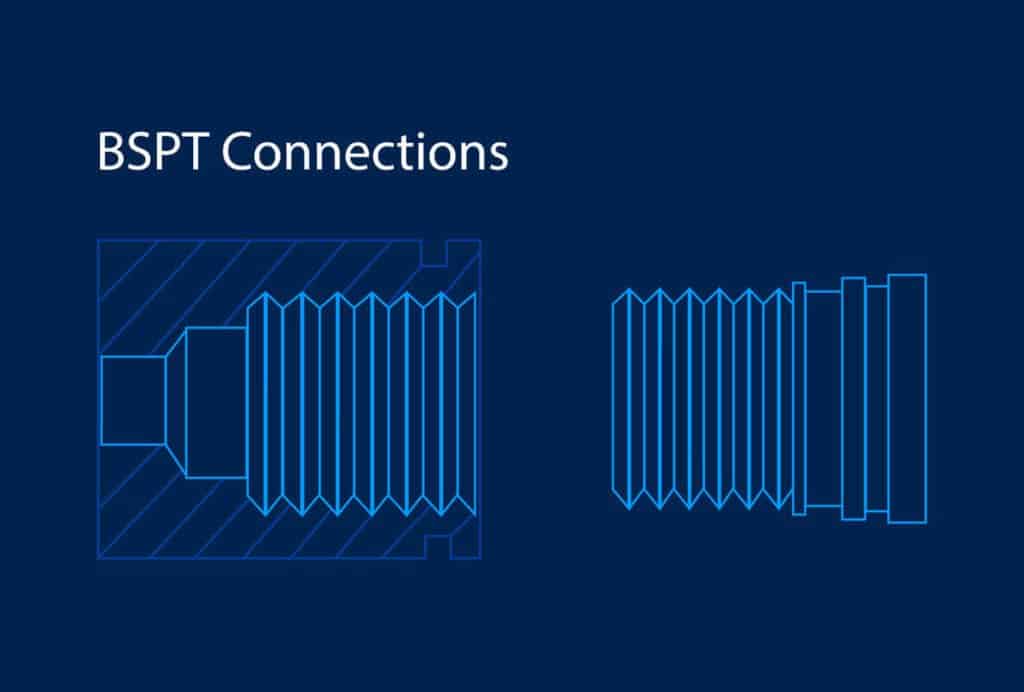

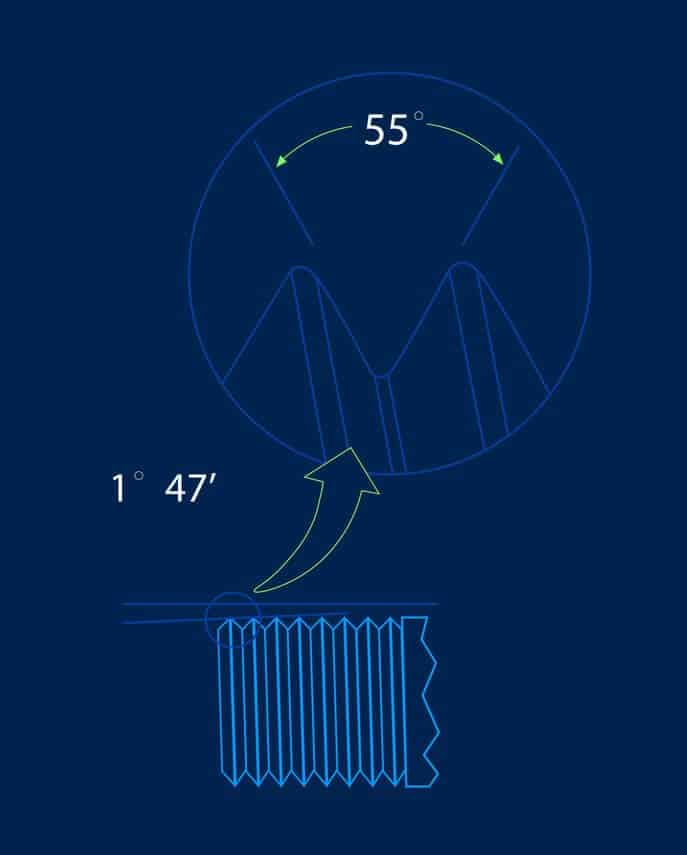

A British Standard Pipe Taper is the standard design for most of the world’s tapered threads. The diameter is widest at the shoulder of the connection and narrows toward the tip. Threads are pitched at a 55 degree angle with rounded peaks and valleys.

Unlike NPT tapered connections, both fittings in a BSPT connection do not have to be tapered. For example, a female fitting can be tapered while the male is straight. No matter the case, a thread sealant must be used in BSPT connections. An NPT tapered connection will sometimes fit into a BSPT fitting, or vice versa, but they will not create an effective seal.

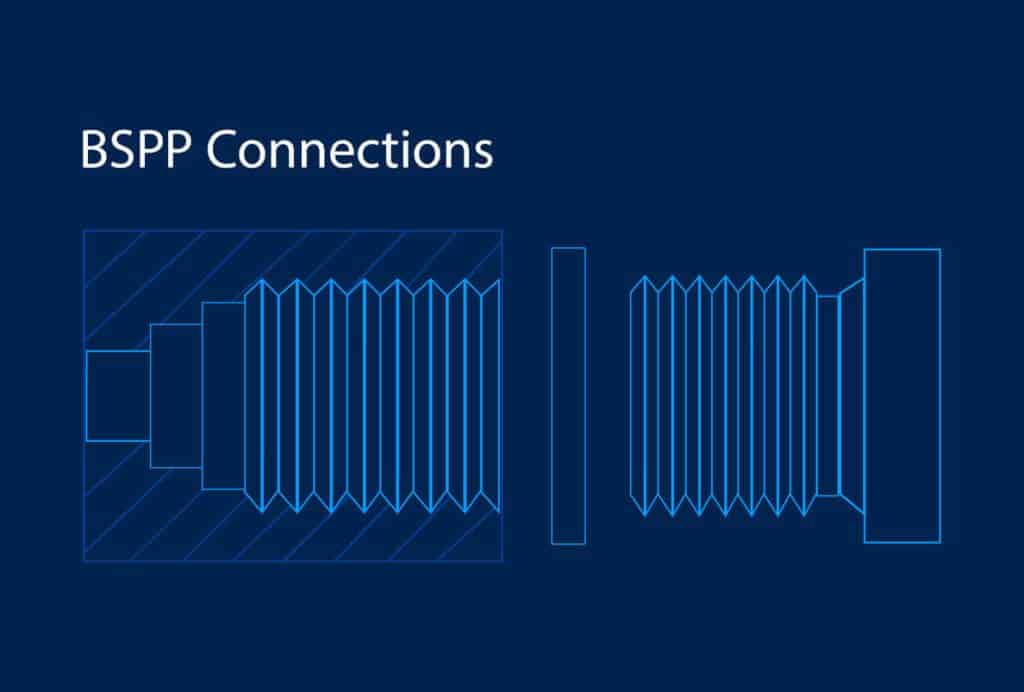

What is a BSPP Thread?

A British Standard Pipe Parallel is the straight equivalent of a BSPT thread. BSPP connections require a bonded seal ring, which is sandwiched in between the shoulder of the male fitting and the face (opening) of the female fitting.

Unlike other connections, a BSPP connection does not need thread sealant.

How to Tell the Difference Between NPT vs. BSP

While the difference between straight and tapered threads is apparent to the naked eye, it is much more difficult (almost impossible) to tell the difference between an NPT or BSP fitting by sight.

If you’re unsure which kind of fitting you’re working with, you’ll need a pitch gauge to measure the angles of the threads. NPT fittings will have threads with a 60 degree spread while BSP threads will have a 55 degree spread.

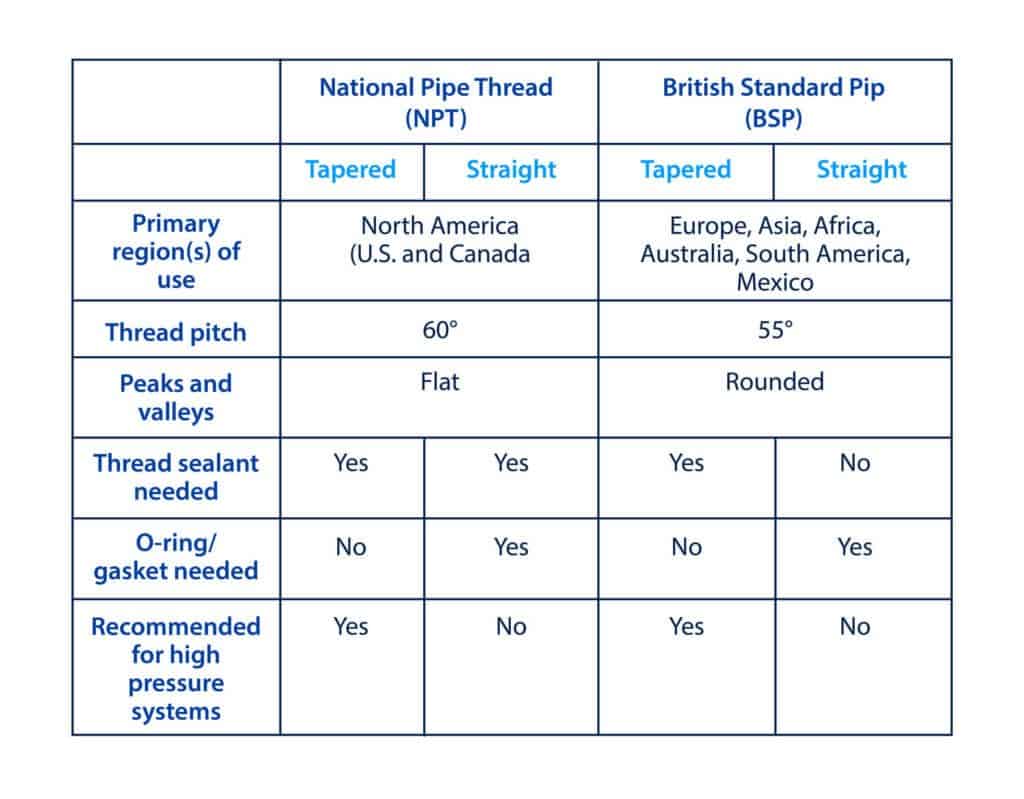

Use this chart to easily compare NPT and BSP.

How to Measure Threads

Whether you’re working with NPT or BSP fittings, you’ll typically be able to tell the difference between tapered and straight connections. However, if a fitting is extremely small or has a subtle taper, you may not be able to tell which it is.

Follow these steps to determine your thread type:

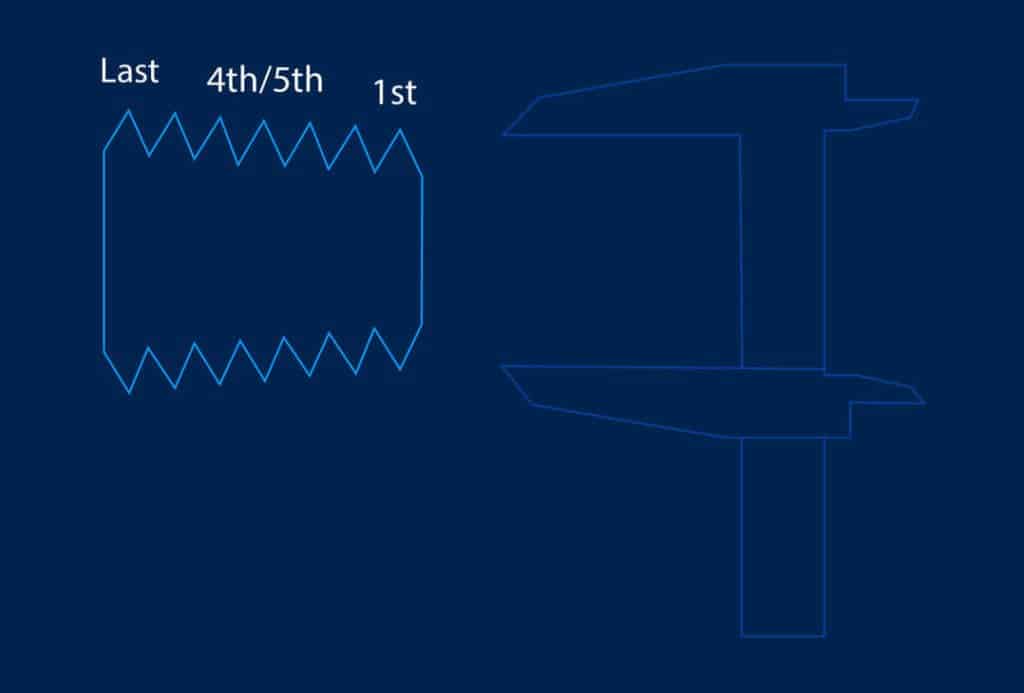

- Using a caliper, measure the major diameter (OD) at the first full thread following the tip of the connection.

- Starting at the tip, count four threads in.

- Measure the diameter at the fourth thread.

- Measure the diameter at the last full thread before the shoulder of the connection.

- If the diameter remains the same, it is a straight thread connection.

- If the diameter increases from the first thread to the last thread (male) or decreases from the first to last thread (female), it is a tapered thread connection.

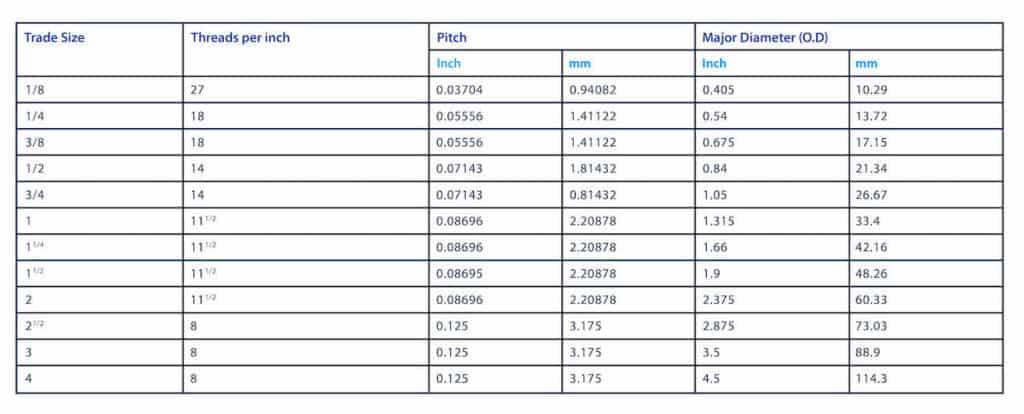

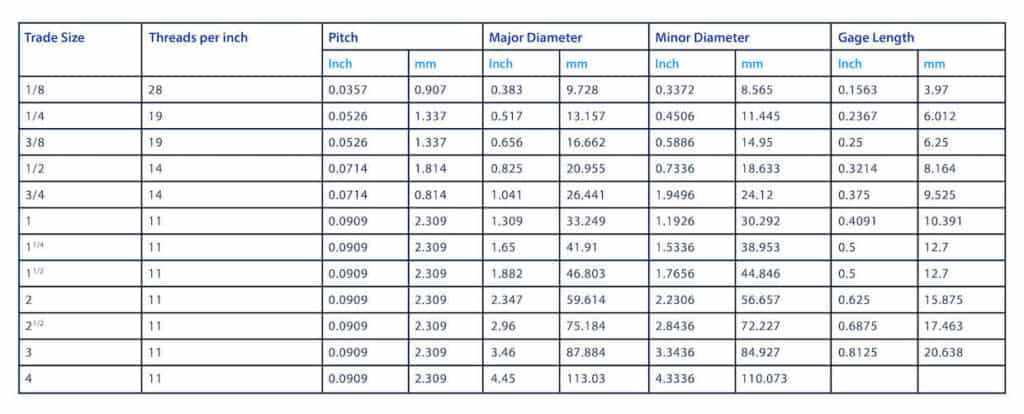

To determine the pitch of the connection (or the severity of its taper), count the number of threads in a 1” span. Once you have this number and your measurements, you’ll need a trade size chart to translate them — fitting sizes are categorized by their trade size, rather than their actual measurements. For example, a ½” NPT does not necessarily measure exactly ½” in diameter.

To find the trade size of a straight thread connection, simply measure its diameter at the fourth thread and consult a trade size chart.

NPT Trade Size Chart

BSP Trade Size Chart

Have More Questions? Call Gemini Valve

Generally speaking, NPT is used for valve connections in the U.S. Occasionally NPT is used internationally, but BSPT governs many European threaded valves. For large volume orders, Gemini Valve will manufacture BSPT valves on a made-to-order basis, but NPT are by far the more popular and common choice.

If you have further questions about valve connections, or would like to request a quote, reach out today. A Gemini Valve team member will be happy to discuss connections for your next project.

BSP & NPT Conversion Size Chart & Guide

Explore essential insights into pipe threading standards with our British Standard Pipe (BSP) & National Pipe Thread (NPT) Conversion Guide.