Valve & Pipe Connections Explained: Threaded, Flanged, Welded & More

What is a Valve Connection?

Valve connections are the components of a valve that connect to the plumbing and allow the valve to join with the piping system. There are six main types of connections used to install valves and other process components in piping systems, and each type has its pros and cons:

- Threaded

- Welded

- Flanged

- Compression

- Union

- Manifold-mount

When choosing a type of valve connection, it’s important to consider these factors:

- Adherence to industry and/or plant standards

- Cost

- Ease of installation

- Ease of removal for repair or replacement

- Inventory simplification

- Leakage prevention

- Permanence of the valve

- Pressure rating/system pressure

- Weight and size

Your system’s specifications will determine the type of connection that will be most effective.

The Benefits of Threaded Ball Valves

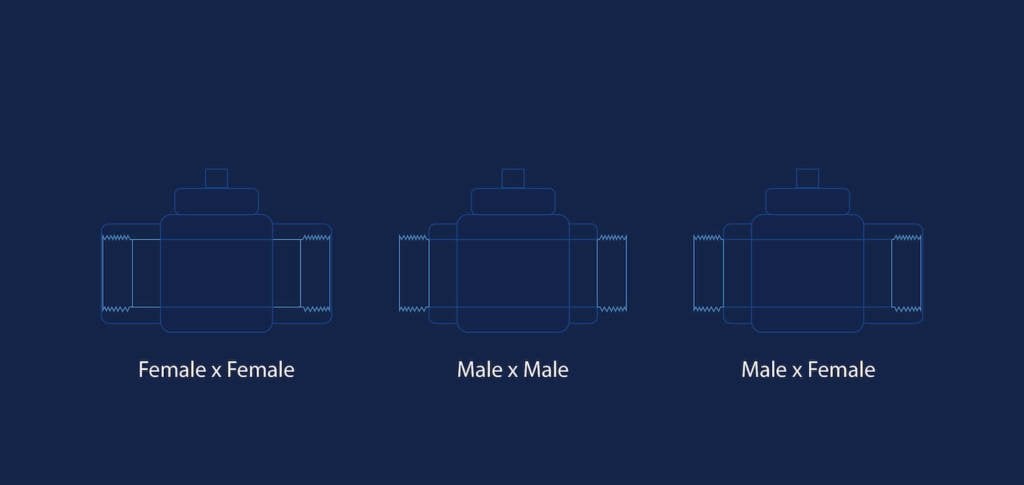

Threaded valve connections are one of the most common valve connection types. This valve style incorporates a screw-type design to integrate with the piping system. There are three primary configurations for threaded valve connections:

- Female x Female

- Male x Male

- Male x Female

Threaded valve connections provide a tight seal and streamlined connection between the valve and pipe. Valves will most commonly have female threaded connections that fit over the end of a male threaded pipe. The threads on both the valve and pipes must adhere to the same standard thread design in order to be compatible.

Ball valves that incorporate threaded connections are easy to install, maintain and replace, are inexpensive and ideal for smaller applications. Threaded connections are typically preferred in applications that feature ball valves with a diameter less than 4 inches. This is because connections with larger diameters are more difficult to seal and thus prone to leaks through the threads.

Even with smaller threaded ball valve connections, pipe tape or sealant between the male and female threads is recommended as a precaution. Both provide extra sealing, and sealant also acts as lubrication and prevents metal-to-metal contact and galling.

Threaded Ball Valve Connections (Straight vs. Tapered Connections)

As we mentioned above, there are industry standards that govern thread design. Threaded connections can either be straight or tapered, and the exact specifications are determined by three sets of standards: National Pipe Thread, British Standard Pipe and Metric (more on these below).

Straight threaded connections maintain the same diameter along their entire length and require a washer or soft O-ring seal to stay leak-tight. Tapered threads, as the name suggests, taper in diameter toward the end of the connection. Tapered connections do not require an O-ring seal, but still need pipe tape or sealant to achieve a leak-tight seal.

National Pipe Thread (NPT)

National Pipe Thread (NPT) is the standard for piping thread design in most of North America (excluding Mexico). NPT threads are unified and pitched at a 60 degree angle with flat peaks and valleys, and can be either straight (NPS) or tapered. When male and female tapered threads are connected, they pull tight against one another to create a leak-tight seal.

NPT specifications are defined by ASME B1.20.1. Sizes are classified by the connection’s major diameter in inches followed by “NPT” (4 NPT).

British Standard Pipe Threads (BSP)

British Standard Pipe (BSP) threads are accepted in most parts of the world besides the U.S. and Canada. BSP threads are unified and pitched at a 55 degree angle with rounded peaks and valleys; like NPT threads, they can be tapered or straight.

Tapered BSP (BSPT) threaded connections require sealant to form a leak-tight seal between the male and female components. Straight or parallel BSP (BSPP) threaded connections do not require thread sealant, since a bonded seal is incorporated into the design.

BSP threads are defined by BS EN 10226-1:2004, BS EN 10226-2:2005 and BS EN 10226-3:2005. BSP sizes are specified using the letters R (which stands for rohr, or “pipe” in German) for tapered connections and G (gas) for straight connections, followed by the major diameter in inches (R 2 ½).

Metric Thread Standard (M)

The ISO metric thread standard, or M, is an international, general purpose screw thread standard. M threads are parallel, pitched at 60 degrees and have flat peaks and valleys. The design is defined by ISO 68-1, which was one of the first standards set by the ISO in 1947.

The major difference between M, BSP and NPT threads is that M threads are measured in millimeters. Sizes are specified with M followed by the major diameter and the pitch, separated by a hyphen (M8-1.25). The pitch is the distance in millimeters between the crests of two threads.

Welded Valve Connections

Valve connections can be welded into a piping system to prevent the possibility of leaks. Welded valve connections are typically used in high-temperature and high-pressure systems such as chemical processing, where there is zero room for errors caused by leaks. This is generally considered a permanent installation as the valve will need to be desoldered in order to be removed from the plumbing.

Flange Valve Connections

Flanges are solid metal plates with bolt holes that surround the edge of a valve connection. When a flanged valve is installed in a piping system, the plate can be bolted to another flange on the pipe, creating a secure connection. Flanged connections are often seen in valves larger than 4 inches in diameter and are common in industrial applications. Flanges are easy to install and remove for routine cleanings. Like threaded connections, flanged connections must adhere to strict standards that define the plate design, size and position of the holes and the type of thread in the holes (ASME B16.5 – 2020 and ISO 7005-1:2011).

Compression Valve Connections

There are three types of compression connections:

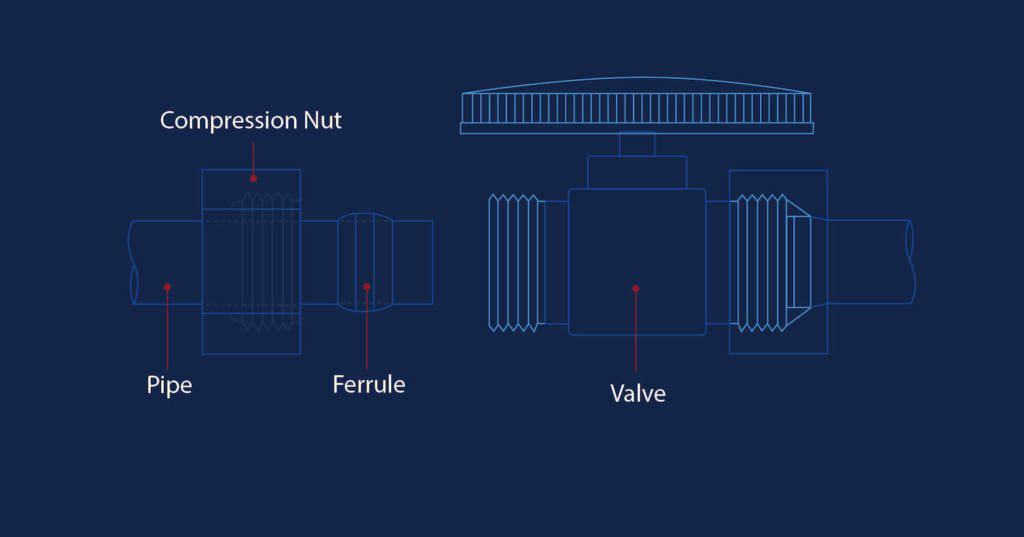

Traditional Compression: A threaded nut and a soft metal cuff called a ferrule are slid over the end of a pipe, then the nut is tightened until it forces the ferrule into the valve socket. The ferrule is compressed between the valve and the compression nut, forming a leak-tight seal. Traditional compression connections are often found in residential plumbing.

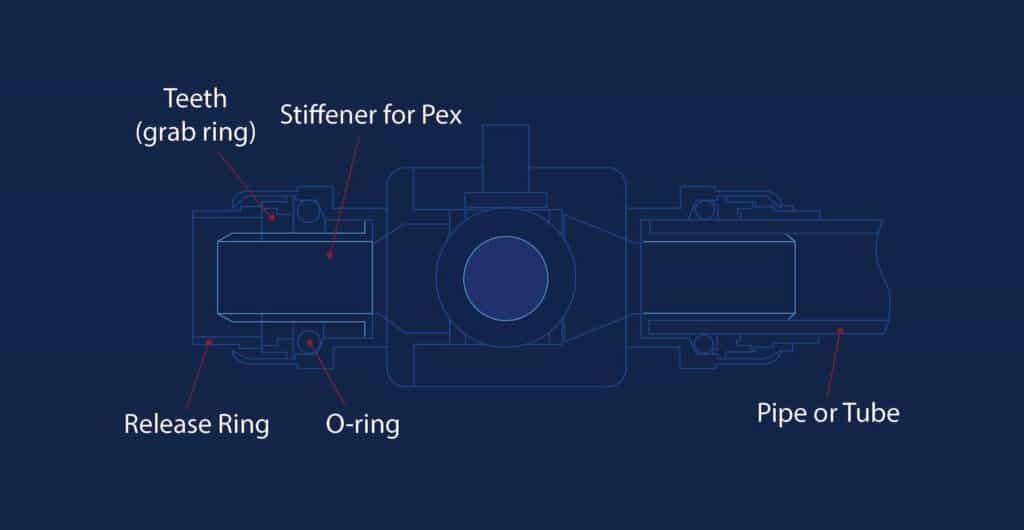

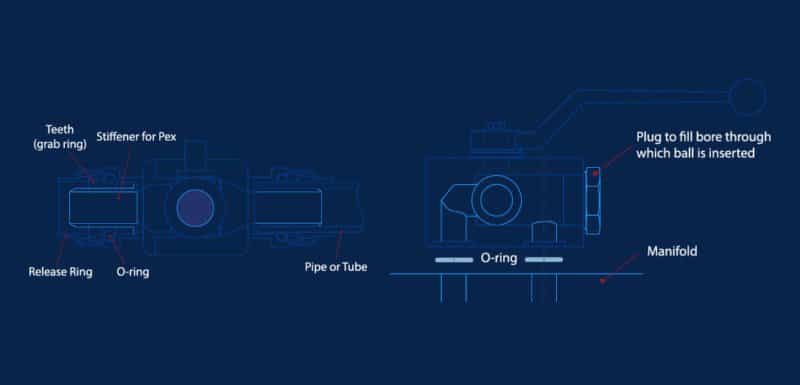

Push-to-Connect: An O-ring inside the valve port that is slightly smaller than the outer diameter of the connecting pipe gets stretched around the pipe and compressed between it and the valve body. A grab-ring with teeth digs into the pipe and prevents it from slipping out, but the pipe can be easily removed by pressing the release ring to retract the teeth. Push-to-connect solutions are often found in residential plumbing systems.

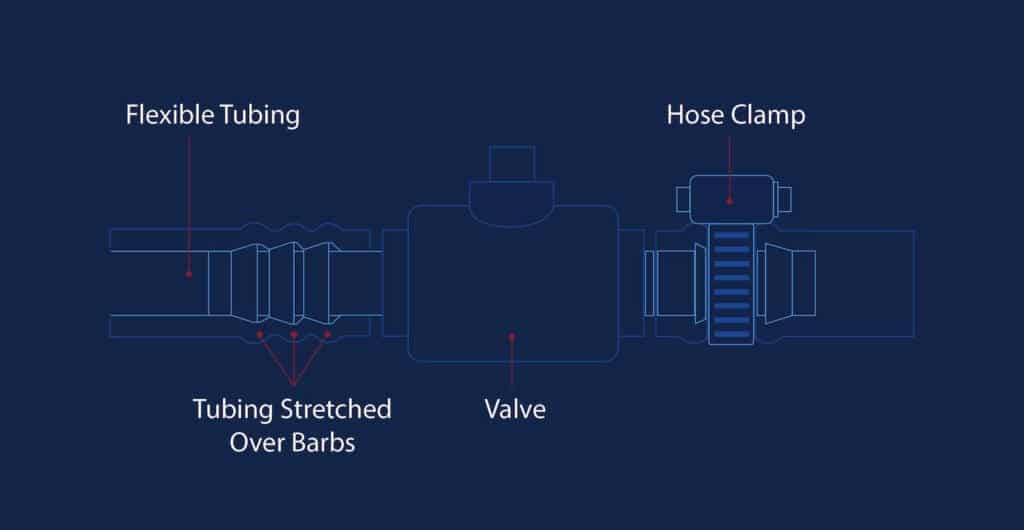

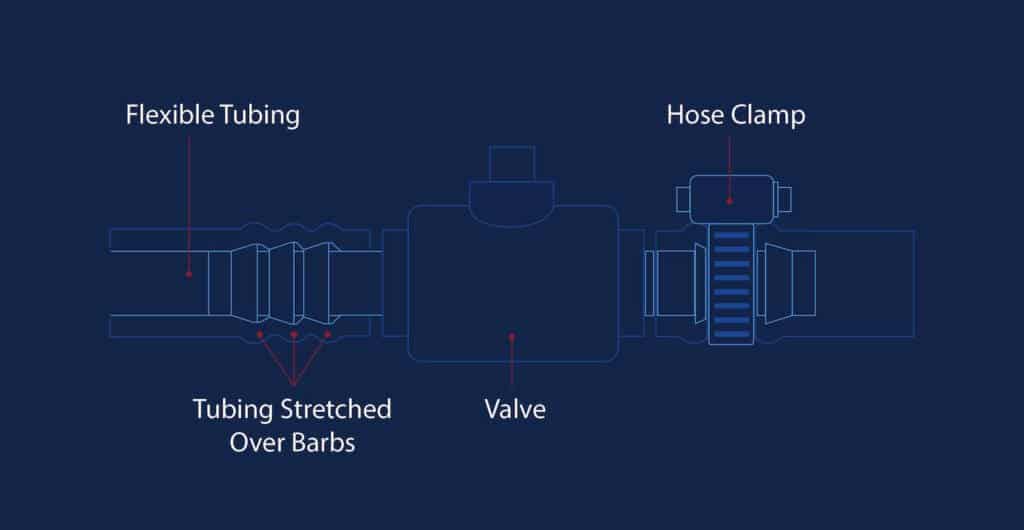

Barbed Hose Connections: Ideal for low-pressure systems, these connections are used to join a soft hose to a valve. The valve has a long end connection with barbs on the exterior, which bite into the inside of the hose as it’s stretched over the connection. The barbs hold the hose in place fairly well, but a hose clamp is recommended to strengthen the connection.

Union Valve Connections

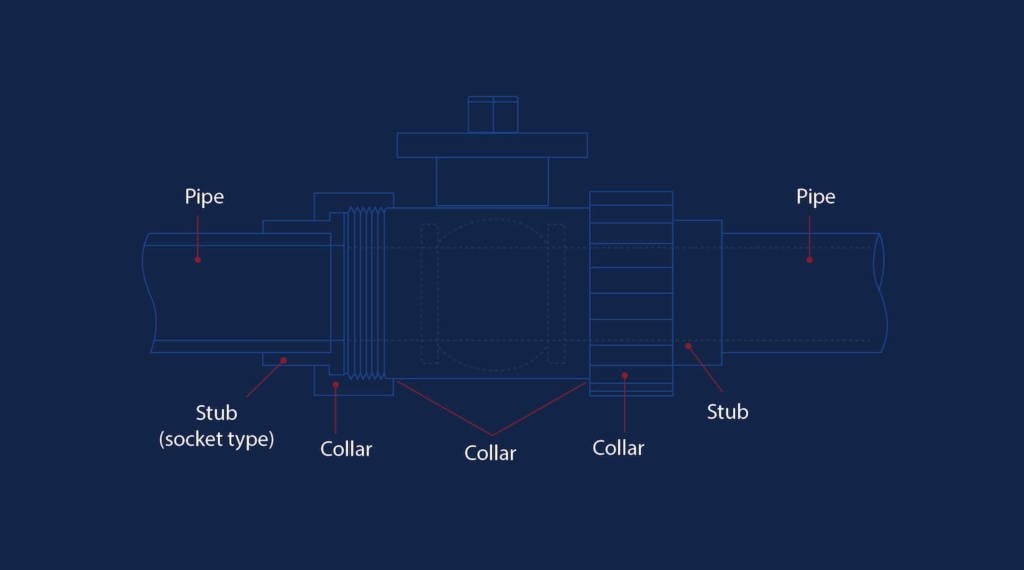

Union valve connections utilize an additional component to join two different connection types together. A threaded female collar nut connects to a male threaded valve end and latches onto a stub that’s fitted onto the end of a pipe.

Union connections allow for fast and easy removal of a valve from the piping system for cleaning or maintenance.

Manifold-mount Valve Connections

Manifold-mount connections are often used to join multiple solenoid valves together, or to attach a solenoid valve to a pneumatic actuator with a NAMUR style mounting interface. A manifold-mount connection incorporates a separate component featuring a flat face with two ports that match the ports on the valve body. The valve is bolted in place on the manifold component and its recessed O-rings are compressed to form a tight seal.

Valve & Pipe Connection Table

There’s a lot to remember when it comes to valve connections! Use this table as a quick reference for the different types of valve connections.

| Connection Type | Applications | Required Accessories | Pros | Cons |

| Threaded (tapered) |

|

|

|

|

| Threaded (straight) |

|

|

|

|

| Welded |

|

|

|

|

| Flanged |

|

|

|

|

| Traditional Compression |

|

|

|

|

| Push-to-Connect |

|

|

|

|

| Barbed Hose |

|

|

|

|

| Union |

|

|

|

|

| Manifold-mount |

|

|

|

|

Explore our selection of threaded, welded and compression connection ball valves here, where you can filter by valve connection type. If you have any questions about which valve connection type will fit your system, send us a note today. The Gemini Valve team is always happy to help.