A Guide to Ball Valve Maintenance

Why is Ball Valve Maintenance Important?

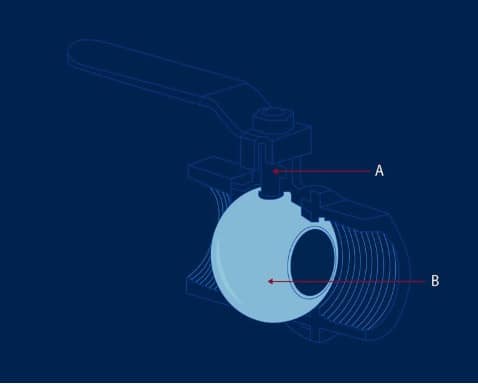

A cutaway of a quarter-turn ball valve. (A) indicates the stem and (B) indicates the rotary ball.

One of the most reliable valve designs used in industrial and OEM applications is the ball valve, a quarter-turn on/off valve with a pivoting ball that controls the flow of gas or fluid media. Ball valves feature a fairly simple design: A hollow ball pivots inside the valve body to allow media to pass through and is controlled by a levered stem that is turned manually or automatically. Compared to gate valves or globe valves, ball valves are often preferred for their:

- Compact, economical designs

- Fast shut-off speeds

- Durability in high-pressure, high-volume and high-temperature applications

- Resistance to corrosion or damage

- Long service life

- Versatility in a range of industrial applications

Ball valves are designed for gas and fluid handling in process systems servicing the oil and gas, chemical processing and agriculture industries. They also are commonly used in food and beverage equipment, mechanical engineering and automotive manufacturing and maintenance. Any ball valves present in processing plants should adhere to the American Society of Mechanical Engineers (ASME) standards for process piping (ASME B31.3), which govern the materials, components, design, assembly and more present in the piping system.

In spite of their durability — or perhaps because of it — ball valves experience significant wear and tear over their lifetime. Most ball valves are designed to be maintenance-free and are intended to eventually be replaced rather than repaired. For this reason, three-piece ball valves are often a good option in high cycle or high-pressure applications where valve seals are likely to experience wear and tear at an accelerated rate. In such applications proper preventative measures can significantly extend the life of your ball valves.

Benefits of Maintaining Your Ball Valves

Longevity

Valves that last longer and require few to no repairs help save money, prevent downtime and keep plant production on schedule. Without routine maintenance and quality checks, any issues with your ball valves may be missed, leading to equipment failures, damaged parts or injured workers.

Security and safety

The worst-case scenario on a plant floor is a preventable accident that causes injuries or costly repairs. Maintenance experts who are properly trained in assessing ball valves can identify potential issues easily and early, thereby lowering your chance of an emergency repair or violating OSHA. When it comes to plant safety, properly installed and maintained ball valves can prevent any hazardous leaks in a piping or processing system.

Reduced need for shutdowns

Downtime is expensive, since any time your plant is not producing is money wasted or revenue missed. Some ball valve maintenance can even be performed while the valve is in operation, allowing plant production to continue uninterrupted.

Cost savings

Just as increased uptime means increased revenue, fewer maintenance issues keep more money in your pocket. If ball valves are regularly inspected, maintained and replaced on a projected schedule, there will be less need to allocate funds to unexpected repairs or replacements.

Factors That Impact Ball Valve Lifespan

Many ball valve manufacturers will provide an estimate of the expected lifespan of a ball valve, and proper maintenance can certainly extend this range. However, ball valve lifespan can be influenced by a variety of other factors.

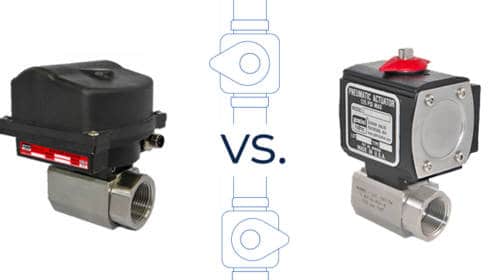

Actuation

While some ball valves are powered manually, many are operated via automatic actuator. Depending on your system’s intended cycle speed, you have your choice between pneumatic (air-powered), electric (motorized) or hydraulic (fluid-powered) actuation. By choosing the appropriate power source for your application, you can reduce maintenance expenses, increase uptime and maximize safety. Pneumatic actuated ball valves are the most durable option in high-pressure environments, provided you have access to compressed air. In most cases, actuators will far outlive the ball valves they control.

Two examples of pneumatic actuated ball valves. The actuator sits on top of the valve body and operates the valve via compressed air.

Design

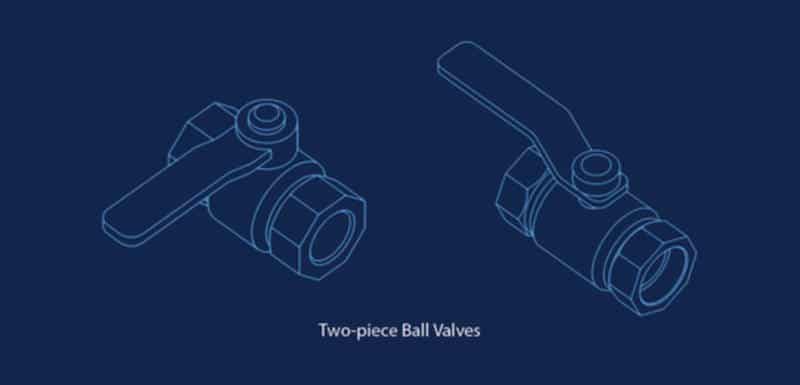

Ball valves come in one-, two- and three-piece designs, the first two of which do not allow for maintenance and must be replaced when components fail. Three-piece ball valves, however, are designed so that the seats and seals can be removed and replaced quickly and easily without removing the entire valve from the system. Provided the valve is made of durable material, the ability to replace components means that three-piece ball valves can long outlive their one- and two-piece counterparts. For this reason, three-piece ball valves are favored for high-cycle and high-pressure applications that subject the seal components to lots of wear and tear.

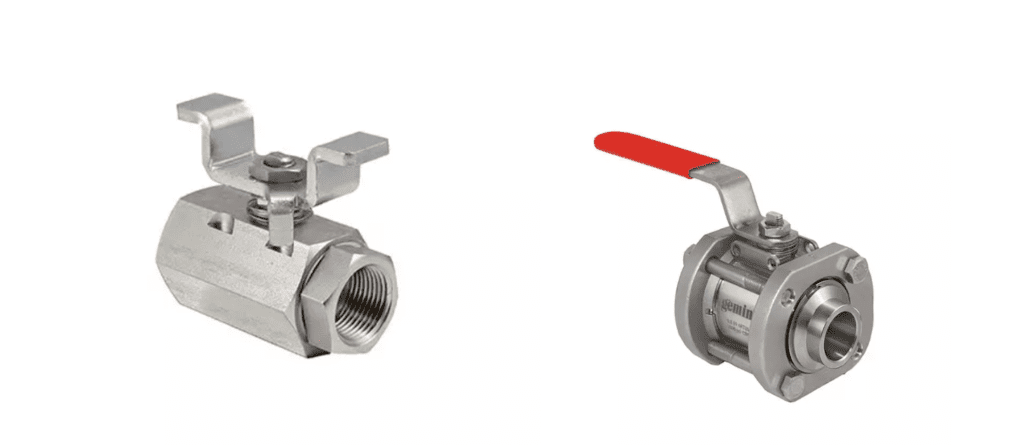

Left: A manual two-piece ball valve; Right: A manual three-piece ball valve.

Serviceability

Seals are typically the first component to fail in a ball valve, since they are made of much softer material than the valve body. While one-piece and two-piece ball valves must be replaced when their seals expire, three-piece ball valves allow for easy replacement of seals without removing the valve entirely.

Temperature and pressure rating

Ball valves used in high-pressure or high-cycle settings will need to be serviced or replaced more frequently than those in lower-pressure applications. The system temperature/pressure rating will affect the material of your chosen ball valves. Be aware that the closer the media’s temperature/pressure rating is to the ball valve’s rating, the more frequently the valve will need to be replaced.

The good news is that the actuator (which is typically the more expensive component in an actuated valve assembly) will normally outlast the ball valve. This means that in most cases the valve can be replaced without replacing the existing actuator.

Media

Ball valves are generally intended for the on/off control of fluids and gases without solid particulates. Any particles in the media can abrade the valve seals, leading to repairs, valve failure or actuator failure. Conversely, lubricative medias such as oils can reduce seal wear and extend the life of the valve even further.

Valve materials

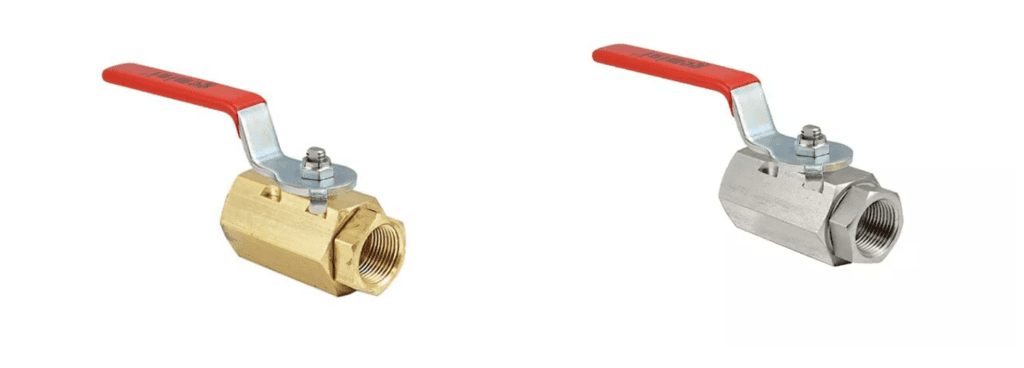

Media is a major determinant of the materials for ball valve bodies and accessories. Ball valves can be made of stainless steel, brass, bronze, or plastic (PVC). While PVC offers flexibility and cost savings, metal ball valves are more durable and able to withstand higher temperatures and pressures. Overall, metal ball valves have a longer lifespan than those made with PVC or other synthetic materials. When in doubt regarding the appropriate valve material, use the Cole-Parmer Chemical Compatibility Database to ensure valve materials are compatible with your specific media.

Left: A manual two-piece brass ball valve; Right: A manual two-piece stainless steel ball valve.

Source

If your plant contains processing equipment made in the U.S., you’ll want to source ball valves from domestic manufacturers and suppliers. Some valve retailers source their products from all over the world, but products from overseas carry the risk of incompatibility with products made Stateside. Quality aside, it’s best to buy ball valves from domestic sources to ensure longevity and prevent premature replacements.

Ball Valve Maintenance [Preventative & Scheduled]

Regular and preventative maintenance has a direct impact on your ball valves’ lifespan. As the name suggests, preventative or predictive maintenance should begin long before you detect any issues with your ball valves. Build the following steps into your maintenance program.

Proper installation

Ball valves that are installed correctly have a much lower chance of needing repairs or replacement. Make sure the engineer installing your valves is experienced and knowledgeable in ball valve installation and maintenance.

Regular cleanings

Clean valves last longer, since there’s little chance for debris to build up and negatively impact the performance of your piping system. Use a towel to wipe dirt, oil or dust from the valve casing and a wire brush to clear any build-up from the valve stem or other moving parts. Be sure you use cleaning agents that won’t react negatively with the valve materials: Gas-based or compressed air cleaners work well for metal components, and alcohol- or water-based cleaners are ideal for non-metal parts. Clean your ball valves at least once a year, and more frequently if the plant environment contains lots of dirt or dust.

Valve lubrication

Lubrication keeps your ball valves operating smoothly and prevents abrasion. Lubrication also helps increase the effectiveness of the valve seals, provided it’s applied properly. Stick to synthetic, water-insoluble, oil-based lubricants; avoid any clay- or solid-based lubricants that may build up inside the valve cavity. Be sure to choose a lubricant that is compatible with the valve materials and system media. Many manufacturers (such as Gemini Valve) permanently lubricate their ball valves before shipment, meaning that additional lubrication later in the valve’s life is unnecessary.

Routine inspections

Have your valves checked by a skilled inspector on a routine basis. For most applications, once a year is ideal, but ball valves in high-pressure and high-cycle applications should receive more frequent inspections. Inspections should address the following:

-

-

-

- Tightness of nuts, bolts and other hardware

- The presence of mineral buildup or corrosion

- Leak hazards

- Proper opening and closure of valves

- Position indicator accuracy (even on static valves)

- Proper exhaustion and air filtration in the area

-

-

Scheduled plant shutdowns

Annual shutdowns are an ideal time to perform ball valve inspections. Remove valves from the piping system, disassemble them, clean the interiors and replace any broken or worn components, paying particular attention to seals or other rubber parts.

With a history spanning over a century, the team at Gemini Valve leverages our years of valve design and manufacturing expertise to help our customers identify the right solutions for their applications. Our primary goal is 100% customer satisfaction — if you have any questions about keeping your ball valves up and running for years to come, we’re your go-to source. Start a conversation with the team today, and we’d be happy to help.

Valve Sizing 101: Your Blueprint for Effective Flow Management

Discover how strategic valve selection impacts flow control processes.