Your Guide to the Best Throttling Valves

What Is a Throttling Valve?

If you need to adjust the flow rate of media anywhere in your piping system, you’ll need a throttling valve. In addition to stopping and starting the flow of liquid or gas media, throttling valves allow system operators to reduce the volume and pressure of the media flowing through the system. In a piping and instrumentation diagram (P&ID), throttling valves are identified using the following symbol:

Throttling valve symbol in a P&ID.

Unlike a control valve, which works by partially opening or closing to change the flow rate of media, a throttling valve does not necessarily need to change position at all, since its sole purpose is to reduce media pressure and velocity in a piping system. For example, a globe valve that remains partially open throughout its entire lifespan to slow the flow of media could be considered a throttling valve.

However, since environmental factors like temperature can alter media flow rate, position control is often required to maintain a consistent flow rate as required by the piping system.

Throttling valves are often called control valves, but the terms are not always interchangeable. Control valves are valves that allow for the control of flow rate through the use of a positioning actuator, which has the ability to precisely control the position of the valve. Throttling valves, on the other hand, are used specifically to reduce media velocity or pressure in a piping system.

Put simply, nearly all control valves can be used as throttling valves, but not all throttling valves are control valves because a throttling valve does not necessarily require dynamic valve position control.

What Types of Valves Have Throttling Capabilities?

Globe valves

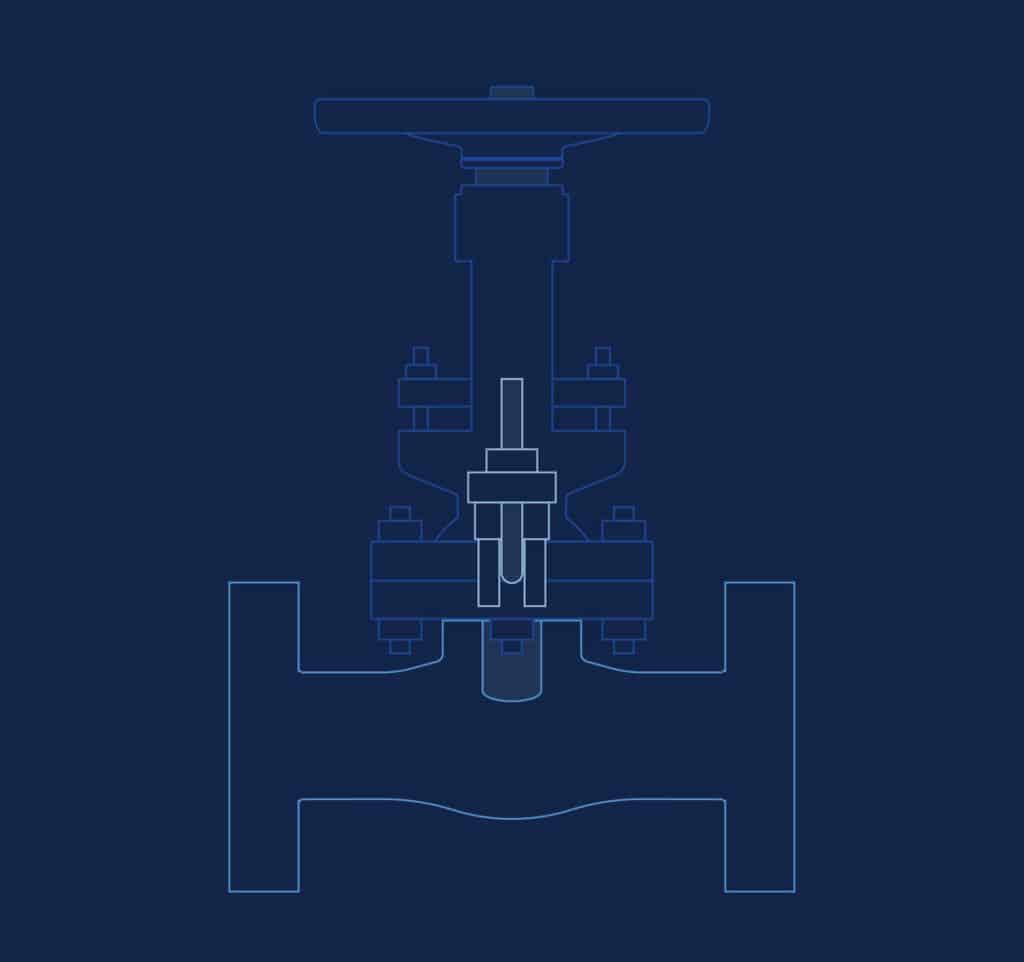

Considered the industry standard for throttling valves, globe valves can stop, start and regulate the flow of media very effectively due to their design. When passing through a globe valve, media must take a slight vertical detour up through the valve cavity, where it meets a plug-like disc. This disc sits on the end of a rotating stem, which turns to raise or lower the plug.

Globe valve cutaway.

Since the media slows naturally when it encounters the vertical detour, the valve encounters less resistance as it closes. Globe valves are less susceptible to damage than other types of valves, since the media flows parallel to the plug rather than perpendicular. Globe valves are frequently used to throttle media in high-pressure systems.

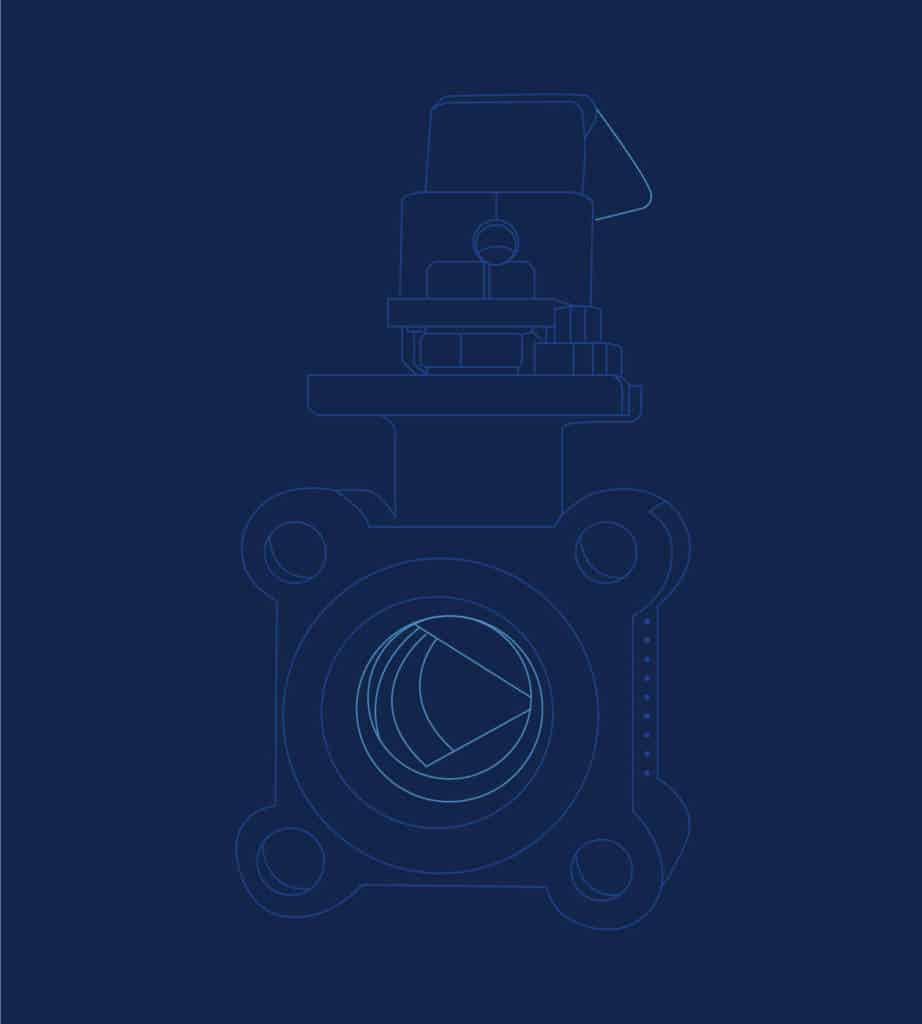

Butterfly valves

A member of the quarter-turn valve family (like ball valves), butterfly valves are often used in applications with limited space. These valves feature a flat disc perpendicular to the media flow that rotates to stop or release media. Butterfly valve throttling is achieved while the disc is in a partially open position; however, since the disc is always in the path of the media, butterfly valves are susceptible to erosion over time. They are often found in water distribution systems.

A butterfly valve.

Gate valves are not intended for throttling. They are designed such that media flowing at high velocity can vibrate and quickly erode or tear a partially-open valve disc off its seat. In a pinch, gate valves should only be used for throttling when the gate is 90% closed.

Can a Ball Valve Be Used as a Throttling Valve?

While they are excellent at providing a tight seal for gas and fluid media, ball valves are not intended for throttling purposes. The amount of torque required to turn a ball valve lever simply does not allow for precise calibration or adjustments, especially in the nearly-closed or mostly-open positions.

Though it is difficult to precisely calibrate flow rate through a ball valve, they are still frequently used as cost-effective throttling solutions. If necessary, ball valves can be used for throttling in:

- Systems that don’t require precise adjustability or control

- Low-pressure applications

- Systems with inexpensive or expendable media

As an example of this last point, if you need to maintain the level of water in a tank within a few inches, ball valves should provide a suitable throttling solution. V-port ball valves will enable the most accurate adjustments in these situations.

V-port ball valves

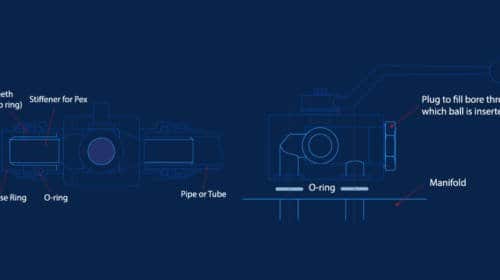

While most ball valves have a round hole, or port, that allows media to pass through the center of the rotating ball, V-port ball valves feature a port shaped like a V lying on its side. The tapered opening allows for a more gradual release and halting of media, making it easier to control flow rate.

A V-port ball valve.

Throttling Valves: Common Applications

Throttling valves are necessary in the following residential, commercial and industrial applications:

- Refrigeration

- Air conditioning

- Hydraulics

- Steam-powered systems

- Pharmaceutical processing

- Chemical processing

- Food processing

- Fuel oil systems

- Other high-pressure, high-temperature settings

The following considerations should be taken into account when determining whether a system needs or can accommodate a throttling valve:

Size of pipes: The larger the pipes, the more limited a valve’s throttling capacity. As the volume of media increases, regulating flow becomes more difficult, even for automatic actuators. Additionally, larger valves are accompanied by larger components that take up more valuable space.

Actuation: A manual actuator may not deliver the throttling accuracy you need. Determine whether your system’s flow pressure requires an automatically actuated control valve for precise calibration.

Material compatibility: Valve materials should always be compatible with the media they handle. Certain chemicals or other substances can erode certain valve materials more quickly, so be sure to check compatibility when choosing valves.

Temperature and pressure: Throttling media often results in an increase in temperature and pressure. It’s critical to note whether the system standards allow for these fluctuations before installing a throttling valve.

Connections: Make sure that you can adapt your valve to fit your existing pipe connections. You should not have to adapt your pipe system to fit the valve.

Have more questions about throttling valves? At Gemini Valve, we’re always glad to talk about ball valve capabilities and help you choose the valve that best suits your needs. Give us a call or send us a message today.

Elevate Your Professional Insight on Valve Selection

Our comprehensive eBook provides a deep understanding of valve types, selection criteria and industry applications. Equip yourself with the best.