Ball Valve Weights By Size & Type With Chart

Ball valve weight is a crucial factor, influencing various aspects of industrial operations, from installation procedures and system design to valve selection and cost considerations. Here, we explore the importance of understanding ball valve weight and the factors that contribute to it.

Ball Valve Weight: Why Is It Important?

The weight of a ball valve is more than just a number. It’s a key detail that affects safety, how well systems work and how much operations cost. This is true at every step, from when a valve is first installed to while it’s maintained years later. It’s important for anyone picking out, installing or maintaining ball valves to understand how weight comes into play. Here’s a closer look at why it matters:

- Installation Safety: Ball valves — particularly larger ones or those made of denser materials — can be heavy. Knowing the weight is crucial for safe installation, as it helps determine the necessary precautions and equipment to prevent damage or personal injury.For instance, heavier valves may call for specialized lifting equipment or additional personnel to ensure a safe and efficient installation process.

- System Design: The weight of a ball valve significantly influences the design of systems like piping networks. Since the system around the valve has to bear its weight, this needs to be factored in when planning the design.For example, heavier valves may require more robust support structures or additional reinforcement, which can impact the overall design and cost of the system.

- Valve Selection: The weight of a ball valve can sway the selection process. Lighter valves may be preferred for easy handling and installation, while heavier valves might be better suited for durability and withstanding operational pressures.For instance, systems that require frequent maintenance may utilize a lighter valve due to ease of removal and replacement.

- Cost Implications: The weight of a ball valve directly impacts logistical aspects like transportation and handling. Heavier valves can increase transportation costs and necessitate special handling equipment during installation. Understanding the weight helps predict these additional costs, leading to more accurate budgeting and decision-making.

- Impact on Maintenance and Longevity: The weight of a ball valve can also significantly impact maintenance procedures and the valve’s longevity. Heavier valves — often made from more durable materials — may require less frequent maintenance and have a longer lifespan.However, they may also require more specialized maintenance procedures due to their weight and complexity. On the other hand, lighter valves may need more frequent maintenance but can be easier to handle and replace if necessary.

Factors That Determine Ball Valve Weight

Several elements play a role in determining the weight of a ball valve. Each of these components, from the physical size of the valve to the type of materials used, has a role in determining the overall weight. By exploring these factors, we can gain a deeper understanding of why different valves have different weights and how this can impact their use in various applications. Let’s examine these factors more closely:

- Valve Size: Larger valves are heavier due to the increased amount of material used in their construction. Valve size is typically measured in terms of its nominal pipe size (NPS), expressed in inches. For instance, a 2-inch ball valve generally weighs less than a 4-inch valve. However, the weight can also vary depending on the specific design and material composition.

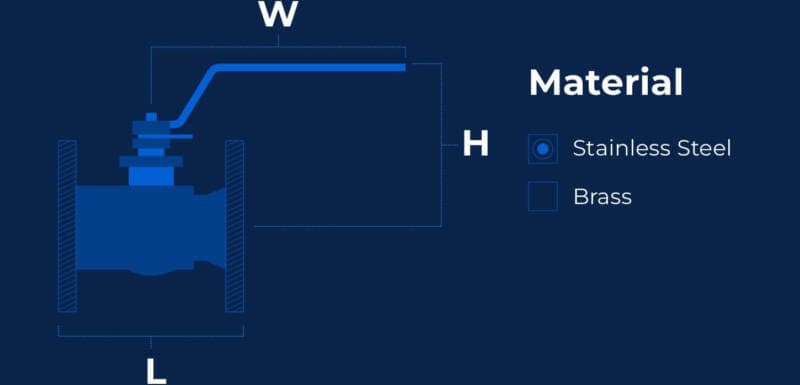

- Material Composition: The material of the valve significantly influences its weight. Each material has advantages and disadvantages, which should be considered when selecting a valve.

- Stainless Steel: Known for its high corrosion resistance and strength, stainless steel is a heavy material. Stainless steel ball valves tend to weigh more than those made from other materials. They are ideal for applications that call for durability and resistance to extreme temperatures and pressures. However, their weight can make them more challenging to install and handle.

- Brass: Brass is another popular choice for ball valves. It offers excellent machinability and cost-effectiveness. Brass valves are lighter than stainless steel but weigh more than plastic or composite materials. They are suitable for applications where moderate temperature and pressure conditions exist. However, they may not be as durable or corrosion-resistant as stainless steel valves.

Related Resource: Brass vs. Stainless Steel Ball Valves: Which Is Better? >>>

- Plastics and Composites: Materials such as PVC, CPVC, PTFE and reinforced nylon are lighter than metal, making ball valves composed of these materials the lightest option. These materials are resistant to corrosion and are often used in applications involving water, certain chemicals and other corrosive media. However, they may not be suitable for high-temperature or high-pressure applications.

- Valve Style: The construction style of a valve also affects its weight. For example, a 3-piece serviceable valve typically weighs more than a standard 2-way valve due to the additional components. This additional weight can provide benefits in terms of serviceability and durability but may also require additional support structures during installation. This is typically only required in larger pipe sizes.

- Presence of an Actuator: Perhaps the most significant overall factor when considering ball valve weight is whether the valve will be operated by an actuator. The type of actuator attached to a ball valve can add significant weight. Manual actuators are typically lightweight, while pneumatic and electric actuators can substantially increase the valve’s overall weight, especially for smaller pipe sizes. The choice of actuator can significantly impact the overall weight and functionality of the valve and should be carefully considered during the selection process.

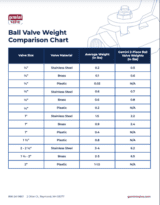

Ball Valve Weight Comparison Chart

To better understand the factors influencing ball valve weight, refer to the following table, which provides a quick yet comprehensive view of the various sizes, materials and weights of ball valves across the industry and with Gemini Valve specifically.

Valve Size Valve Material Average Weight (in lbs) Gemini 2-Piece Ball Valve Weights (in lbs) ¼” Stainless Steel 0.2 0.5 ¼” Brass 0.1 0.6 ¼” Plastic 0.03 N/A ½” Stainless Steel 0.6 0.7 ½” Brass 0.6 0.8 ½” Plastic 0.2 N/A 1” Stainless Steel 1.5 2.2 1” Brass 0.9 2.4 1” Plastic 0.4 N/A 1.5” Plastic 0.8 N/A 2–2.5” Stainless Steel 3–4 6.2 1.5–2” Brass 2–3 6.5 2” Plastic 1–1.5 N/A It’s also important to keep in mind that the use of an actuator can impact the weight of a ball valve. Valve actuator weights can vary significantly based on several factors, including:

- The type of actuator: There are several types of actuators, including manual handwheel actuators, pneumatic actuators, hydraulic actuators and electric actuators. Each type has its own weight characteristics.

- The size of the valve: Larger valves require larger actuators, which generally weigh more.

- The construction material: Actuators can be made from a variety of materials, including various types of metal and plastic. The weight of the actuator will depend on the density of the material used.

- The design of the actuator: Some actuators are designed to be lightweight, while others are designed to be robust and heavy-duty.

The Final Weigh-In: Importance of Ball Valve Weight

Understanding the intricacies of ball valve weights is crucial for optimizing performance and cost-efficiency in your operations. The weight of a ball valve affects every stage of its lifecycle, from installation and system design to maintenance and replacement. By considering ball valve weight alongside other factors such as material composition, valve style and the presence of an actuator, you can make informed decisions that enhance the efficiency and longevity of your industrial systems.

For a detailed reference, download our Ball Valve Weight Comparison Chart. This resource offers a comprehensive view of the factors affecting ball valve weight, helping you make informed decisions when selecting valves for your operations. Remember, the right valve can make a significant difference in the performance and cost-effectiveness of your operations.

How does valve weight impact your piping systems?

Gain heavy duty Insights on ball valve weight with our downloadable chart.