Brass vs. Stainless Steel Ball Valves: Which Is Better?

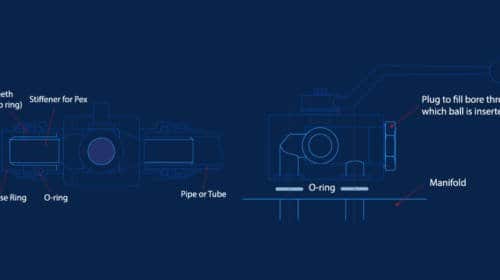

Ball valves are often used in shut-off and control applications to control the flow of materials through a piping system. These valves have a long service life and provide reliable sealing over time, even when they are not consistently used over long periods. Unlike some other valve types, ball valves are typically more resistant to contaminated materials.

Ball valves are used in various industries, such as:

-

-

- Oil and gas

- Food and beverage

- Automotive

- Power processing

- Pharmaceuticals

- Manufacturing

-

Some of the most common applications that call for the use of ball valves include:

-

-

- Chemical admixtures and treatment

- Irrigation and water treatment equipment

- Vehicle wash systems

- Outdoor hoses

- Washing machines and dishwashers

-

While ball valves can be made from a variety of different materials, two of the most commonly used are those made from brass and stainless steel. Keep reading to learn more about stainless steel ball valves and brass ball valves to help determine which is best for your next application.

What Are Stainless Steel Ball Valves?

Stainless steel is a resilient metal that is made by combining an iron alloy with chromium and nickel. This durable material is ideal for shut-off and control applications, as stainless steel ball valves are known to be effective at resisting leaks, able to withstand a wide range of temperatures and perform well in high-pressure conditions.

Stainless steel ball valves offer a long-lasting option, even when used in highly corrosive environments; 316 stainless steel is a particularly corrosion-resistant alternative that includes more nickel than standard stainless steel, as well as the addition of molybdenum — a silvery metal with a very high melting point. This combination makes 316 stainless steel ball valves more resistant to chlorides and therefore well suited for applications in marine environments.

What Are Brass Ball Valves?

Ball valves can also be constructed from brass, a metal composed of copper, zinc and occasionally other metals. Brass ball valves may include small amounts of lead (often less than 2%). However, due to potential health risks posed by lead, the Federal Drug Administration (FDA) only approves the use of certified lead-free brass ball valves.

The first component to fail in a metal ball valve will almost always be the soft seals. This means that in most applications a brass ball valve will last just as long as a stainless steel ball valve before it begins to leak. If your application does not require a corrosion-resistant metal, brass will offer equal longevity to stainless steel.

Additionally, brass ball valves tend to accept welding better than stainless steel, making brass a more versatile option in some industries and applications.

Applications For Stainless Steel Ball Valves

Because stainless steel ball valves are resistant to corrosion, high temperatures and high-pressure environments, they are frequently used in industrial processes, manufacturing and construction. Some of the most common applications for stainless steel ball valves include:

Applications For Brass Ball Valves

In most applications, brass ball valves will offer equal performance and longevity to stainless steel ball valves. However, in applications with very extreme pressure or temperature requirements, stainless steel or other even more durable materials may be better suited. That being said, the soft seals, typically made of P.T.F.E., will still be the weakest link. This means specialized seal materials would also be required in these extreme applications.

Brass ball valves are frequently used in residential and commercial plumbing, water wells, HVAC and many other applications. Certified lead-free brass ball valves must be used in certain applications — such as those that involve drinking water or food processing — to meet FDA regulations.

The bottom line: brass ball valves are a more economical choice as long as no highly corrosive materials are flowing through the valves.

Stainless Steel Ball Valves vs. Brass Ball Valves

| Stainless Steel Ball Valves | Brass Ball Valves | |

| Material Composition | Iron alloy made from nickel and chromium (and sometimes molybdenum) | Copper alloy that includes zinc and occasionally additional metals |

| Cost | More costly than leaded and lead-free brass ball valves | Less costly than stainless steel ball valves, more costly than plastic ball valves |

| FDA Approval | Approved by the FDA for use in the food and beverage industry | Not approved by the FDA unless certified lead-free |

| Softness | Harder than brass, making it more challenging to seal (for example, by welding) | Softer than stainless steel, making it more easy to seal (for example, via welding) and more efficient to machine |

| Corrosion Resistance | Highly corrosion resistant; the preferred material for use in corrosive environments, including marine applications | Can withstand corrosive environments better than plastic but not as well as stainless steel; however, can be compatible with some materials not compatible with stainless steel |

| Pressure Ratings | Higher pressure ratings than brass; more resistant to high pressure | Lower pressure ratings than stainless steel; less resistant to high pressure |

| Temperature Resistance | Can handle and last longer at higher temperatures than brass ball valves | Not as suitable for high temperature situations as stainless steel ball valves |

When compared to brass ball valves, stainless steel ball valves hold up better in corrosive environments, withstand higher temperatures and pressures and pose no health risks when used in food and beverage applications.

However, brass ball valves are less costly and offer more versatility in processes that require welding. Both ball valve options can provide the right solution when used under appropriate conditions.

If you’re not sure which ball valve to select for your next project, contact an expert at Gemini Valve today, and we’ll be happy to assist.

Are you interested in the development and design stages of chemical, physical, electrical and mechanical processes but not sure how to read piping and instrumentation diagrams and symbols? Learn everything you need to know about P&ID symbols by downloading our How to Read P&ID Component & Valve Symbols ebook today!