Ball Valve Dimensions Explained

When it comes to ball valve sizes, there’s more to it than meets the eye. For some applications, it may be relatively straightforward, but selecting the ideal ball valve dimensions may require considering numerous factors beyond the pipe size.

To ensure the best performance and longevity of a valve, you’ll need to consider the:

- Gas or fluid type

- Viscosity, pressure and pressure differential

- Flow rate

- Required flow characteristics

The importance of choosing the correct valve size, style and material cannot be overstated. A poorly selected valve may lead to premature or unexpected failure, with potential consequences such as cavitation, flashing, erosion, vibration or corrosion. By paying close attention to ball valve dimensions and selecting the appropriate components, you can significantly reduce the likelihood of valve failure and optimize system performance.

In this guide, we’ll help you navigate the essential aspects of ball valve dimensions, providing valuable insights to help you make informed decisions when selecting the ideal valve for your application.

How Is Ball Valve Sizing Determined?

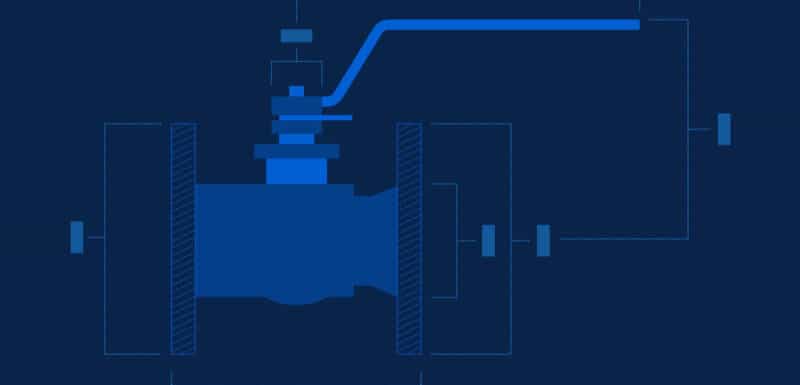

Gaining a clear understanding of ball valve dimensions is crucial in selecting the right valve for your application.

It starts with three key elements involved in ball sizing:

- The flow rate: Your operation’s process engineering requirements often dictate the ball valve size needed. Flow rate is typically the first consideration when selecting a valve size. Keep in mind that larger bore sizes allow for higher flow rates, so this is an excellent starting point when specifying a new assembly that includes a ball valve.It’s important to note that not all applications require a high flow rate. There are many factors to consider when it comes to the overall flow rate of an application, such as the length of the run the media will be flowing through as well as any twists and turns in the piping. These factors will add friction and cause a reduction in the flow rate.

- Port size: The port size refers to the opening inside the valve that allows fluid or gas to flow through. The size of this opening directly impacts the flow rate, with larger port sizes generally enabling better flow rates.For some applications, the shape of the port can also be an important factor to consider. Standard ball valves have a circular port which creates an exponential increase in flow while the valve cycles. V-port ball valves are often used in applications where precise flow control is required. When choosing a ball valve, it’s important to think about the flow rate needed for your specific application and select a port size that can handle it. Use our calculator to determine your specific valve flow coefficient.

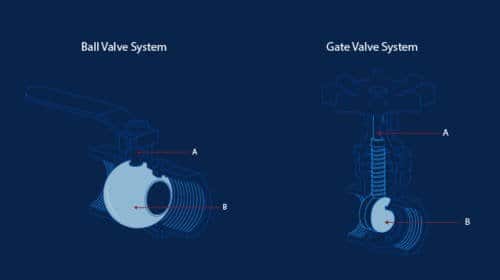

- The valve construction: The design of the ball valve plays a significant role in sizing. Ball valves come in two main types based on their construction: reduced bore and full bore. Reduced bore valves have a smaller port size than the connecting pipe, while full bore valves have a port size equal to the pipe size. The type of construction you choose will affect the flow rate of the fluid or gas flowing through the valve, potentially impacting the efficiency and performance of your system.For the majority of applications, a reduced port or standard port valve will not be the bottleneck and will therefore have no impact on the overall flow rate. In these applications, you may be able to cut down on cost with a standard port valve.

Selecting the right ball valve size for your specific needs is crucial to ensure optimal performance and efficiency. Here’s how you can determine the appropriate valve size for your application.

Specifying Ball Valve Sizes Based on Existing Threaded Fittings

In certain situations, you may need to determine the appropriate ball valve size based on your existing fittings. You can use your current fittings to select the right ball valve size. To do this, you’ll need the following measurement:

- External measurement of the male thread on the fittings: Similarly, if the external diameter of the male thread is close to a particular size, you’ll need a ball valve of the same size. A 2″ external diameter, for instance, would require a 2″ ball valve.

If you don’t have access to this measurement, consider the following alternatives:

- Review site drawings or plans: Check if there are any site drawings or plans that provide product specifications for the fittings in question. This information can help you determine the required valve size.

- Consult with your supplier: If all else fails, don’t hesitate to contact your friendly supplier for assistance. They should be able to help you identify the appropriate ball valve size based on the information you provide about your existing fittings.

By using these methods, you can ensure that you select the correct ball valve size to match your current fittings and maintain optimal system performance.

Common Dimensions of Class 150 Flanged Ball Valves

Familiarizing yourself with the most common dimensions for Class 150 flanged ball valves — including the valve body size, port size and valve end connection size — is crucial for selecting the right valve for your application.

To measure ball valves accurately, follow these steps:

- Valve body size: Measure the distance between the two flanges or connecting points of the valve. This measurement helps determine the size of the valve body.

- Port size: Measure the internal diameter of the valve’s flow passage. This measurement represents the port size and affects the flow rate through the valve.

- Valve end connection size: Measure the diameter of the connecting points, such as flanges, threads or other end connections. This measurement ensures compatibility with your system’s piping or hoses.

Once you have these measurements, you can compare them to the following chart of common dimensions for Class 150 ball valves:

| Valve Body Size | Port Size | Valve End Connection Size |

| 1/2″ | 0.375″ | 1/2″ NPT, 1/2″ Flanged |

| 3/4″ | 0.5″ | 3/4″ NPT, 3/4″ Flanged |

| 1″ | 0.875″ | 1″ NPT, 1″ Flanged |

| 1-1/2″ | 1.25″ | 1-1/2″ NPT, 1-1/2″ Flanged |

| 2″ | 1.75″ | 2″ NPT, 2″ Flanged |

| 3″ | 2.875″ | 3″ NPT, 3″ Flanged |

| 4″ | 3.875″ | 4″ NPT, 4″ Flanged |

Note: The dimensions listed in the chart are approximate and may vary slightly among manufacturers.

Choose the Right Ball Valve Sizes with Confidence

Understanding ball valve dimensions is essential for selecting the right valve for your specific needs. Accounting for factors such as flow rate, hose size and the type of ball valve (reduced bore vs. full bore) will ensure optimal performance and longevity of your piping system. Additionally, using the STAMP framework and measuring existing fittings will help you make informed decisions when specifying ball valve sizes.

To further assist you in your quest for the perfect ball valve, we encourage you to download our comprehensive guide: 15 Factors to Consider Before Your Next Industrial Ball Valve Order. This valuable resource will provide additional insights and tips to help you choose the ideal ball valve for your application. By following these guidelines, you can improve the efficiency and success of your piping system, ultimately saving time, money and effort in the long run.

15 Factors to Consider Before Your Next Industrial Ball Valve Order

This guide includes everything you need to know before placing your next industrial ball valve order.