How to Read Ball Valve Markings: WOG, CWP, WSP & More

Ball valve markings are purposeful codes and abbreviations intended to help users identify the right product for a specific application. Markings are used for two reasons:

- To show the standards to which the ball valve has been tested.

- To show the applications where the ball valve can be used.

Ball valves are constructed with various types of materials, components, ball designs, actuation methods and beyond — there are hundreds and hundreds of options and manufacturers use a variety of different types of markings.

Understanding those markings is challenging if you don’t know what you’re looking for. Read on for an explanation of the most important markings, complete with visual examples.

General Ball Valve Markings

Note that the information shown on the valve body will vary depending on the manufacturer. The following is general information that you may find on the body of a ball valve in the U.S.

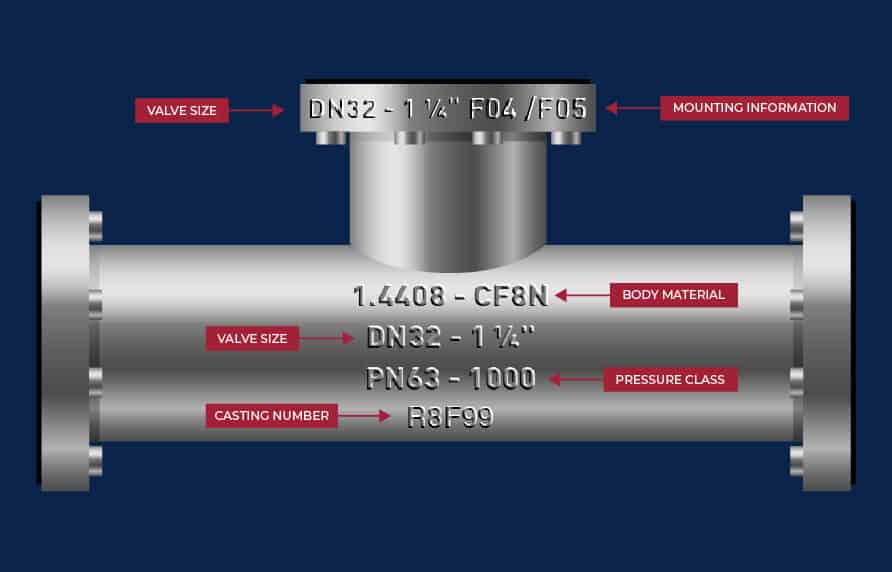

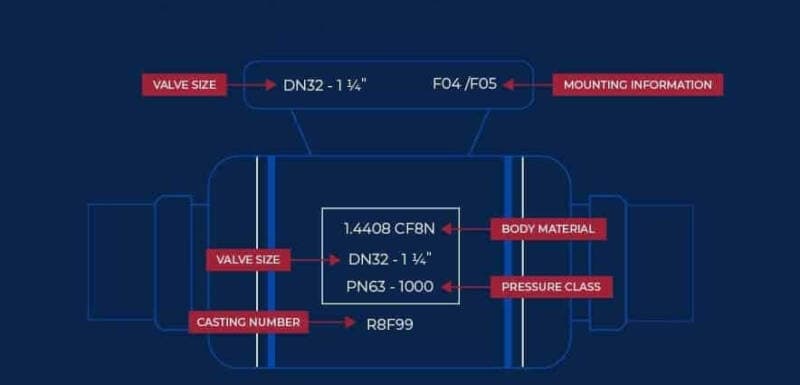

Valve Size: The valve pipe size is often simply noted in inches, however, you may also find the pipe size noted with a DN prefix. This stands for “diameter nominal” and the number following the prefix is the valve pipe size in millimeters.

Mounting Information: If your valve utilizes an ISO-standardized mounting configuration to mount the valve to the actuator, this is where you will find that information.

Body Material: This specifically states the type of material used to create the valve body. For example, CFM8 is the code for cast 316 stainless steel.

Pressure Class: “PN” refers to pressure nominal. The number after PN indicates the pressure class of the valve in bars, where 1 bar equals 14.5038 PSI. Some manufacturers may simply list the pressure rating in PSI as well.

Casting Number: The casting number is used to track materials and batches. There may be more than one of these, depending on the valve.

Lead-Free: Some valves will be marked with an “LF” to indicate they are lead-free.

Manufacturer Information: The manufacturer’s name should be on the valve body.

Model Number: The model or part number of the valve is the manufacturer’s identification process.

Related Reading: What is a Ball Valve? Parts, Actuation, Diagrams & More >

Ball Valve Ratings

Ball valve ratings indicate the type of application where it is suitable for use. These ratings will be marked on the valve body.

PSI Rating

Pounds per square inch (PSI) is a measurement of pressure that is commonly used in the U.S. for equipment and instruments. A ball valve’s PSI measures the pressure of the media that flows through the valve as it comes in contact with a square inch of pipe or other fittings.

CWP & WOG Ratings

Cold working pressure (CWP) indicates the valve’s maximum pressure rating at temperatures between -20°F to 100°F. This is commonly referenced alongside the valve’s pressure rating. For example, 720 CWP indicates the valve is rated to 720 PSI within the CWP temperature range.

WOG (water, oil, gas) is an older term that is no longer used as frequently as it once was. It simply means that the valve is intended for use with water, oil, or gas, with the exception of combustible gases.

WSP Rating

Working steam pressure (WSP) indicates the maximum steam pressure that a ball valve can withstand at the highest temperature rating. This might also be marked as SWP, meaning steam working pressure.

Gas Ratings

Only certain ball valves are approved for use with combustible gases, and these will have specific markings that explain where they can be used. Some of these include:

Indoor Gas Ratings:

- ½ PSIG (PSI gauge): This low-pressure rating is used for gas valves that are used in appliances.

- 5G: This is a higher pressure rating for valves used in household gas piping systems.

Outdoor Gas Ratings:

- CAN/CGA-3.16: This is the Canadian gas pressure rating for both outdoor and indoor valves used in gas piping systems.

- BRS125G: This is a U.S. gas pressure rating for valves in gas piping systems.

Please note that the above information is intended to be used as a base guideline only. Care must be taken to ensure the valve you choose is a good fit for your specific application requirements. If you are unsure, it is always best to speak directly with the manufacturer or distributor about your application.

Related Reading: 15 Factors to Consider Before Your Next Industrial Ball Valve Order >

Testing & Quality Assurance Ball Valve Markings

To ensure that products are manufactured to the highest quality, the following organizations perform rigorous tests and certification processes. Ball valves that prove their worth are marked accordingly.

Uniform Plumbing Code (UPC): A UPC certification mark shows that a ball valve complies with both the individual product’s performance standards and the standards set by the International Association of Plumbing and Mechanical Officials (IAPMO).

American National Standards Institute (ANSI): ANSI sets various standards for the manufacturing, installation and use of ball valves. You will most often see this mark on flanged ball valves.

Underwriters Laboratories (UL): UL is a global safety certification company that tests a wide variety of products (including ball valves). You’ll see the UL logo on valves that have passed the various scientific testing processes they utilize.

How to Read Ball Valve Markings [Downloadable Cheat Sheet]

This resource provides a helpful “cheat sheet” for identifying and interpreting ball valve markings at a glance.