Understanding Valve Pressure Drop

Valve pressure drop is a critical factor in the design and operation of fluid systems. Understanding this concept is crucial for anyone involved in designing, operating or maintaining fluid-based systems, including engineers and technicians. Accurate knowledge of valve pressure drop aids in selecting the right valves and optimizing system operations. Read on to learn more about valve pressure drop and how to calculate it using a simple pressure drop formula.

What Is Valve Pressure Drop?

Valve pressure drop refers to the decrease in pressure of a fluid, whether liquid or gas, as it moves through a valve. This pressure reduction is crucial in controlling and regulating fluid flow within a system.

Pressure drop is related to energy changes that occur within the fluid. These changes are characterized by:

- Energy transformation: Shifts in heat, volume (more noticeable in gas) and pressure

- Enthalpy conservation: Total energy of the system remains constant despite these changes

Factors Affecting Valve Pressure Drop

To optimize the design and functionality of fluid systems, you first need to understand the factors that influence valve pressure drop. These range from the specific type of valve in use to the properties of the fluid flowing through it.

Valve Type

The kind of valve in use plays a significant role in determining pressure drop. For example, check valves, designed to allow fluid to flow in one direction only, have unique characteristics that influence pressure drop.

Valve Size and Design

The size and design of a valve also directly affect pressure drop. Two key design factors include:

- Orifice (also known as port) size: Larger orifices generally allow for more fluid flow with less resistance, resulting in lower pressure drop.

- Internal flow path: The design of the flow path within the valve can increase or decrease resistance and thus affect the pressure drop.

Fluid Properties

The characteristics of the fluid flowing through the valve also play a crucial role:

- Viscosity: Thicker fluids (higher viscosity) tend to create more resistance, leading to higher pressure drops.

- Density: Heavier fluids (higher density) can also contribute to increased pressure drop due to the greater force required to move them through the valve.

Flow Rate

The rate at which fluid moves through a valve also impacts pressure drop. Higher flow rates generally lead to higher pressure drops, as more fluid volume creates more resistance within the valve.

Relationship Between Pressure Drop and Flow Rate

The relationship between pressure drop and flow rate is critical in designing and operating fluid systems.

Flow rate is calculated based on how much fluid moves through a system (such as a pipe) over time. Pressure drop is the decrease in pressure from one point in the system to another.

Generally, the flow rate of a system increases when there’s a higher pressure drop. This happens because greater pressure is needed to push more fluid through the system.

To understand the relationship between flow rate and pressure drop, consider the effect of adjusting the orifice size in a garden hose. If you increase the flow rate by enlarging the orifice (for instance, by using a nozzle with a wider opening), the pressure needed to move the liquid through the valve decreases. This is because a larger opening provides less resistance to the fluid’s flow. On the other hand, reducing the orifice size, such as placing your thumb over the hose’s end, increases the pressure after the valve (P2 in the formula below). While the water exits the hose with a higher velocity, indicating increased pressure at the exit, the flow rate actually decreases.

Understanding the relationship between flow rate and pressure drop is vital for system integrity. Engineers use this knowledge to ensure systems have enough flow without wasting energy on too much pressure. Knowing how these two concepts interact also helps in choosing the right valves and designing the system to work effectively at the desired flow rate without unnecessary pressure loss.

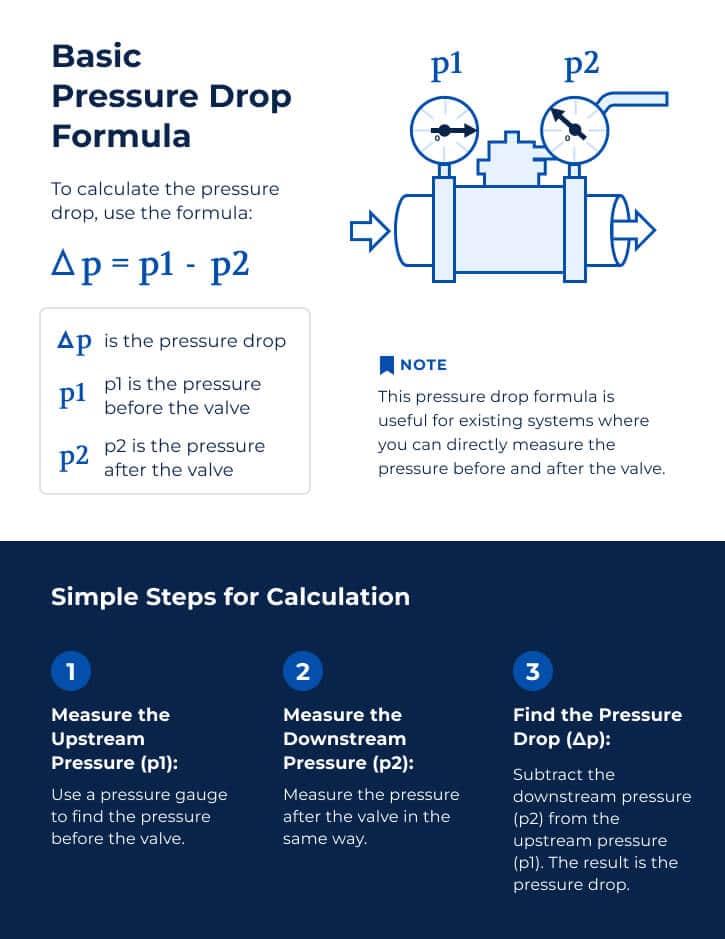

Calculating Valve Pressure Drop

Calculating the pressure drop across a valve is essential for understanding how it will affect system performance. Here’s a straightforward guide to performing this calculation.

Using CV Calculators for More Complex Systems

In systems where you can’t measure pressure directly, or for new designs, you can use a CV (flow coefficient) calculator. This tool considers the valve’s characteristics, flow rate and fluid properties to estimate the pressure drop.

Remember, while this method can provide an estimate, actual pressure drop can vary due to factors like fluid type and system layout. These calculations are a starting point, but a more detailed analysis may be necessary for precise results.

Valve Pressure Drop and Valve Selection

It’s important to understand valve pressure drop when selecting valves for fluid systems, as it can impact both the durability and performance of the valves. When choosing valves for systems with significant pressure drops, you’ll need to consider several key factors to ensure the valves function optimally over their lifespan.

Valve Lifespan

A valve’s operational longevity depends on numerous factors, especially when used in high pressure drop systems. These factors include the following:

- Impact of pressure drop: The pressure drop a valve experiences can significantly affect its lifespan, particularly in high pressure drop scenarios.

- Forces on valve seats: In high pressure drop conditions, valve seats experience increased force, leading to more rapid wear.

- Wear and tear: The heightened force from higher pressure drops can cause quicker deterioration of valve components.

Valve Material Composition

In environments with high pressure drops, selecting the right materials for valve seats is critical. Engineers often prefer durable materials like graphite or metals for these applications.

These robust materials are capable of withstanding the stresses from high pressure drops, thus extending the valve’s operational life.

Valve Type

It’s essential to choose a valve that not only meets flow requirements but also can handle the pressure conditions of the system without excessive wear.

Different valves respond to pressure drops differently. For example, full port ball valves typically handle high pressure drops more efficiently than globe valves, due to their straight-through flow path.

When selecting valves for any system, understanding and considering the implications of valve pressure drop is vital for optimal system performance and longevity of the valves.

Navigating Valve Pressure Drops with Gemini Valve

The importance of understanding valve pressure drop cannot be overstated. It enables designers and engineers to create systems that are both effective and energy-efficient, reducing unnecessary wear and prolonging the lifespan of the system components. Moreover, this understanding aids in troubleshooting and improving existing systems, ensuring they operate at peak efficiency.

For personalized assistance and access to high-quality valves tailored to your specific system requirements, don’t hesitate to reach out. Request a quote today and benefit from Gemini Valve’s valve expertise and solutions designed to meet your unique needs.