Fail Open vs. Fail Close — Which Is Best?

Valve failure is not necessarily an indication of a valve’s ability to function but rather refers to the default mode that a valve should resort to in the event of power or signal loss. In many piping applications, it is imperative to have a fail-safe valve status set up to protect the system in emergency situations.

The two types of valve failure modes are fail open and fail close. If your system requires the flow process to be halted when power is lost, you would use a fail close valve. On the other hand, if your system needs to maintain a steady flow in the event of a signal failure, you would need to use a fail open valve.

Read on for more information about what causes a valve to fail, the key differences between fail open and fail close and how to choose the right option for specific applications.

What Causes a Valve Failsafe to Trigger?

There are many different scenarios that could lead to a power loss that causes a system to fail. Remember that in failsafe situations, it’s not the valves that are failing but that the power source has been disrupted. Power in this context means the force that moves the actuator, whether air pressure, gas pressure, hydraulic liquid pressure or electric power.

Common reasons for valves to fail include:

- Thunderstorms

- Freezing temperatures

- Loss of upstream pressure

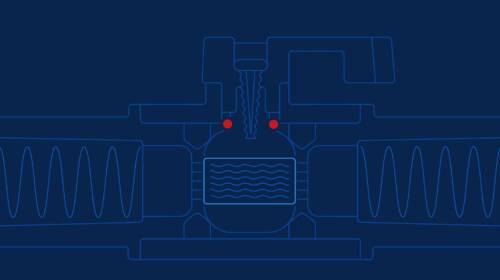

What is Fail Open (FO) - Air to Close?

Fail open valves — also known as spring to open or air to close valves — are commonly used to prevent a buildup of excessive pressure within a piping system when the power or signal is lost. Air to close valves are often used as a result of a blocked line or when a catastrophic failure occurs.

In this fail-safe status mode, the valve:

- Needs power/air pressure in order to remain closed

- Defaults to open when the power or signal is interrupted

- Remains closed when the power is on

Fail open valves are also commonly used in fire extinguishing systems. When power is disrupted by a fire, the valve automatically opens to allow water to flow through the system. Another example air to close application would be a system that controls the flow of cold water entering a heat exchanger, where warm process fluids need to be cooled in order to protect equipment and avoid overheating.

What is Fail Closed (FC) - Air to Open?

Fail close valves are also referred to as air to open valves, since they need air pressure or another power source to stay open. In the event of a signal loss, this helps protect your downstream equipment from excessive pressure.

In this fail-safe status mode, the valve:

- Requires power/air pressure in order to stay open

- Defaults to closed when the power or signal is interrupted

- Remains open when the power is on

Fail closed valves are frequently used to ensure the safety of a project when the valve needs to be immediately closed after the loss of air pressure or another power source. Air to open valves are important safety features in critical applications where pressure or power loss could result in disaster. Fail close valve installation is common in areas vulnerable to leaks, such as pressure vessels, chemical storage tanks and piping systems.

One example of fail close valves in action would be at wastewater processing plants, where treated wastewater is transported into natural water sources. During an emergency power loss situation, it would be necessary for the valve to fail closed so that wastewater does not flow into other water supplies.

Fail Open vs. Fail Close — How To Choose?

Deciding between a fail open valve and a fail close valve is an important step in protecting your system. Choosing the right option is dictated by the specific application and which failure mode will best prevent a hazardous or costly incident in the event of a power failure. For specific questions, it is always best to consult the manufacturer directly regarding your application.

Implementing a fail-safe status into your valve processes could help you avoid catastrophic consequences when power loss occurs. Whether you need to stop media transmission or enable its free flow when the signal is interrupted, it’s important to have the right fail-safe method in place. Still not sure which option is right for your specific project? Contact a member of the Gemini Valve team today for assistance.

How to Read Ball Valve Markings [Downloadable Cheat Sheet]

This resource provides a helpful “cheat sheet” for identifying and interpreting ball valve markings at a glance.