3-Piece Ball Valves: Benefits, Uses & More

One of the main considerations to make when selecting a ball valve is determining what type of body construction will work best for your application. One-piece ball valves are compact and economical, 2-piece ball valves allow for larger port sizes and 3-piece ball valves can be easily repaired or replaced.

Read on to understand the differences between 1, 2 and 3-piece ball valves and the most common uses for each.

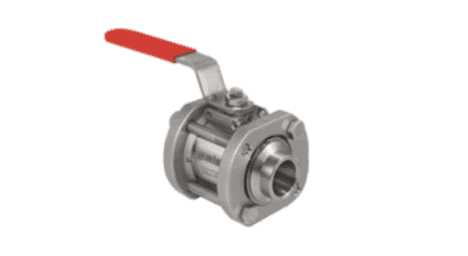

The Construction of 3-Piece Ball Valves

Three-piece ball valves are manufactured with one main body and two pipe connectors. The pipe connectors are typically threaded or welded to a pipe. This enables the main body to be easily removed for cleaning or repairs without having to remove the pipe connectors. Full port and bidirectional shutoff options are also available.

After installing a 3-piece ball valve, wear components — such as balls, ball seats and stems — can be replaced quickly and independently. The biggest benefit here is that the valve can remain in service for its intended lifecycle while operators enjoy low long-term maintenance costs.

When It Makes Sense to Use 3-Piece Ball Valves

Ball valve components in high-cycle and heavy pressure applications experience a lot of wear and tear. Three-piece ball valves are ideal for these applications because replacing and servicing parts can be done quickly and easily.

Three-piece ball valves are most commonly found in manufacturing facilities and are available in a wide variety of connection types, including:

- Female National Pipe Taper (FNPT)

- Socket Weld

- Tube Socket Weld

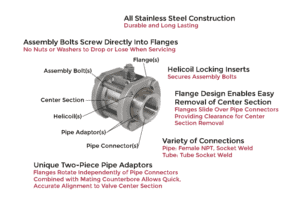

Exclusive in Gemini Valve’s 3-piece ball valves, the assembly bolts can screw directly into the assembly flanges. There are no assembly nuts to be dropped or lost when installing or servicing the valve.

Advantages of 3-Piece Ball Valves

Since the main body of a 3-piece ball valve can be removed for cleaning and maintenance, it is often the most cost-effective option in the long run. Changing seats and seals is more affordable than replacing the entire valve, and not having to remove the pipe connectors prevents a line shutdown should maintenance be required.

Gemini Valve Exclusive

Gemini’s three-piece ball valves feature two-piece pipe adapters that allow flanges to rotate independently of pipe connectors. This, combined with a mating counterbore on the pipe flanges, allows quick and accurate alignment to the valve center section.

What About 1-Piece & 2-Piece Ball Valves?

Of course, 3-piece ball valves are not the only option. There are also 1 and 2-piece ball valves that are intended for certain applications.

A 1-piece ball valve is just that; it consists of a single, solid cast body. These are usually considered to be throwaway valves because they are not designed in a way that makes them easy to repair. Still, these are often the most economical option compared to 2 and 3-piece ball valves.

Two-piece ball valves feature a main body and a single end connection. These can be repaired if removed from service, but this is often difficult due to galling that can occur in the threads when the end plug is removed from the valve body. Like 3-piece ball valves, 2-piece ball valves are also available in full port configurations.

When to Use 1 & 2-Piece Ball Valves

Both 1-piece and 2-piece ball valves are most commonly found in foodservice equipment, liquid filling and automotive fluid filling applications.

One-piece ball valves are not designed to be repaired, so they are not recommended for high-demand applications that require routine maintenance. Two-piece ball valves can be removed from service for maintenance, but this process isn’t as easy as it would be with a 3-piece ball valve.

1-Piece, 2-Piece & 3-Piece Ball Valve Comparison

| 1-Piece Ball Valves | 2-Piece Ball Valves | 3-Piece Ball Valves | |

| Common Applications | Foodservice equipment

Liquid filling Automotive fluid filling |

Foodservice equipment

Liquid filling Automotive fluid filling |

Manufacturing facilities |

| Benefits | Most economical option

Can be replaced at a low cost |

More economical to purchase or replace than 3-piece valves

Available in full port |

Easy to disassemble for maintenance

Long-term cost savings for high-cycle or extreme applications Available in full port Connection options include FNPT, socket weld and tube socket weld |

| Downfalls | Not designed to be repaired | Limited repairability | Higher up-front cost |

Our Serviceable Series of 3-piece ball valves features a self-wear compensating stem seal design to ensure long, leak-tight service. All ball valve products can be custom designed to suit your exact specifications. Contact one of our valve specialists for more information.

Valve Sizing 101: Your Blueprint for Effective Flow Management

Discover how strategic valve selection impacts flow control processes.